![]()

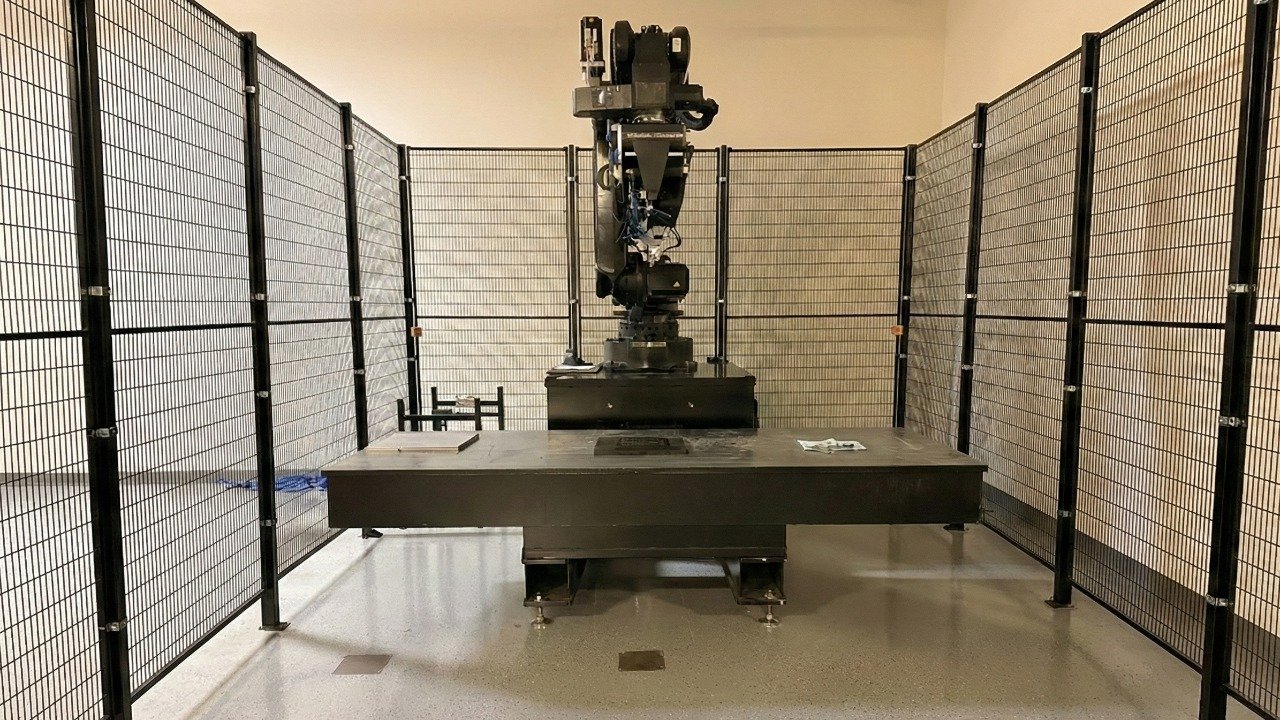

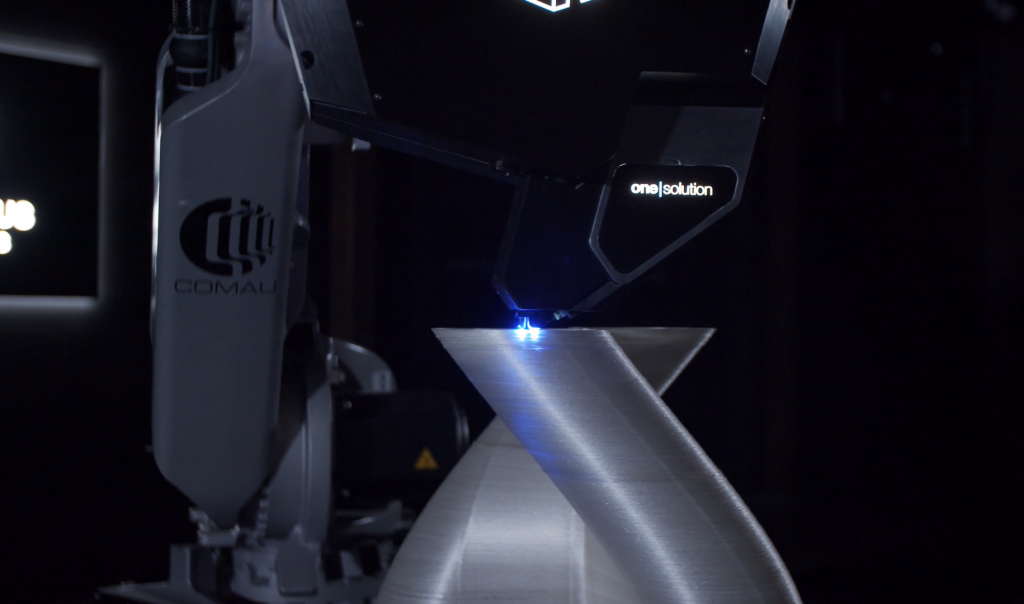

Auburn University, a public land-grant research university, has strengthened its advanced manufacturing portfolio with the addition of a CF3D Enterprise system from Continuous Composites, now installed at the Auburn University Research and Innovation Campus. The new capability reinforces the Huntsville site’s position within a rapidly expanding regional hub for hypersonic research and development.

This investment reflects Auburn’s continued focus on next-generation composite manufacturing. Paired with the CF3D Studio software, the system enables the production of high-performance continuous-fiber composite structures, supporting research efforts that address some of the most demanding challenges in aerospace and defense applications.

A Strategic Location for Hypersonics Research

The Huntsville campus is embedded within a dense network of defense contractors, aerospace companies, and organizations leading key programs. The site hosts the Auburn University Applied Research Institute and offers adaptable laboratories, modeling and simulation tools, secure research spaces, and dedicated areas for interns and graduate students. It serves as Auburn’s primary research and technical gateway in Huntsville.

For the local team, the CF3D Enterprise is both an experimental platform and a strategic asset. Its deployment aligns closely with the region’s emphasis on hypersonics, where advanced composite designs are critical for managing extreme thermal loads and achieving structural efficiency. The system also deepens Auburn’s collaboration with Continuous Composites while supporting partnerships across government, industry, and defense.

“Huntsville continues to be the gravitational center of hypersonic development in the United States, and Auburn is investing where it matters,” said Steve Starner, CEO of Continuous Composites. “The addition of a CF3D Enterprise cell gives Auburn and its partners a modern composite manufacturing capability and a toolset to explore structural concepts that were previously out of reach.”

Enabling Collaboration, Workforce Development, and Outreach

With the CF3D system in place, Auburn researchers can work more closely with the surrounding defense community, shortening development cycles for prototypes and advancing applied materials research. The installation also provides students and faculty with hands-on exposure to digital composite manufacturing.

“Auburn’s presence in Huntsville places us in the center of national-priority programs,” said Luke Boyer, Ph.D., Lead Principal Research Engineer and Advanced Manufacturing Team Lead. “Integrating CF3D into our capabilities expands our support for hypersonic development and gives partners the ability to study structural concepts grounded in real manufacturing data.”

Looking ahead, Continuous Composites will host a CF3D Tech Tour at Auburn University’s Huntsville Research and Innovation Center on March 11, 2026. Held at a Distro C classification level, the event will convene aerospace OEMs, defense primes, research organizations, and government stakeholders for technical exchanges, live demonstrations, and an in-depth look at the CF3D Enterprise Cell. Additional details will be announced in the coming months.

U.S. Hypersonics Momentum Builds Around Advanced Manufacturing

Auburn University’s CF3D installation comes amid a broader acceleration of U.S. investment in hypersonic technologies, as defense and aerospace stakeholders prioritize rapid prototyping, advanced composites, and distributed manufacturing capabilities.

In August, the U.S.-based University of Arizona’s Mach-X engineering team secured a $5 million grant from the U.S. Army to develop an advanced alloy manufacturing process that integrates 3D printing and machine learning. The project focuses on producing critical components for hypersonic vehicles capable of traveling at least five times the speed of sound. By combining AI-driven design with cutting-edge additive manufacturing, Mach-X aims to accelerate development cycles for next-generation hypersonic platforms.

Elsewhere, Venus Aerospace, a Texas-based hypersonic propulsion company, will incorporate a 3D printed nozzle developed under a NASA Small Business Innovation Research (SBIR) award into its upcoming ground-based hypersonic engine demonstration. Produced using laser powder bed fusion, the nozzle is a key element of Venus’s Rotating Detonation Rocket Engine (RDRE) — a compact system designed to operate efficiently across multiple flight regimes without the need for engine switching.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

Featured image shows The CF3D Enterprise Cell. Photo via Auburn University.

Source link

2025-12-18 13:00:00