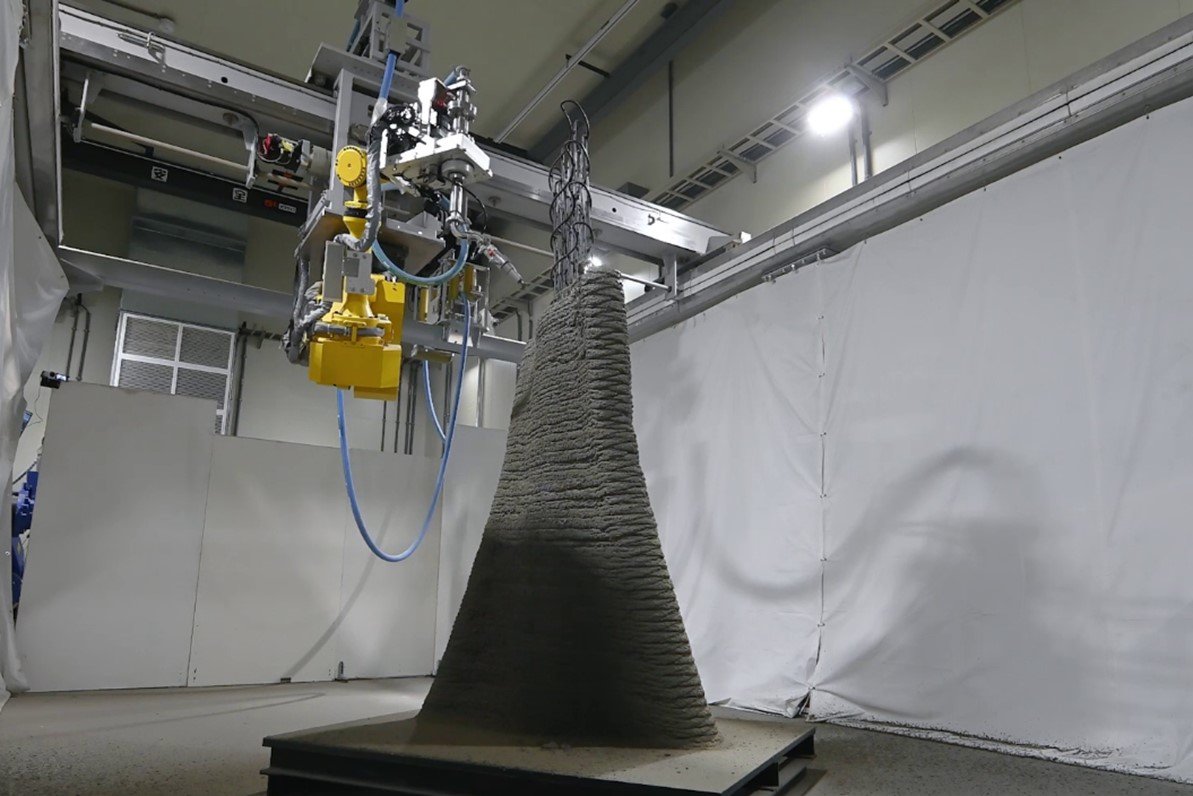

Shimizu Corporation has developed a spray-based 3D concrete printing system designed to construct large, curved reinforced components. The system combines a nine-degree-of-freedom gantry robot with a material spray simulator that can verify sprayed-material behavior before actual printing. The material spray simulator was developed in collaboration with Carnegie Mellon University’s Computational Engineering and Robotics Lab. Credit: Shimizu The system addresses limitations of conventional material extrusion 3D printing methods, which deposit cementitious materials layer by layer but struggle to integrate rebars into printed layers. Spray-based printing allows for better integration of reinforced structural components by spraying cementitious materials to form structures. However, this method has historically faced challenges with printer motion control and fabrication accuracy. The new system uses a material spray simulator to determine optimal printing parameters, including nozzle paths, spray distance, angle, speed, and material discharge volume. The gantry robot features a seven-degree-of-freedom arm suspended from a two-axis XY motion… read more

Alex

Cobra Golf has added two new models to its 3D-printed iron collection, introducing the 3DP MB and 3DP X irons alongside the existing 3DP TOUR model. The expanded lineup aims to serve golfers across different skill levels, from tour professionals to mid-handicap players. The new models will be available for pre-sale on January 6 and at retailers on January 9. A look at the build-out of the internal lattice core in the Cobra 3DP X irons. (Credit: Cobra Golf) The 3DP MB model draws inspiration from prototype clubs created for Cobra staffer Max Homa when he joined the team in 2025. The design features slightly more offset and a thinner topline compared to previous Cobra blade irons. “The first time we hit them, I told (Ben) Schomin (pro tour services manager for Cobra Golf) they felt really good, and they were performing good, the numbers were great, all that was… read more

Airtech has announced its support of Alpha Additive on an ACADIA 2025 project that successfully 3D printed a complex structure featuring multiple 60-degree overhangs using a traditional 3-axis gantry system. The team completed the 3,000-pound, eight-piece structure in a single continuous printing run. Credit: Airtech The project utilized Airtech’s Dahltram T-100GF, a recycled-grade, glass-fiber reinforced thermoplastic composite resin designed for pellet-fed large format additive manufacturing (LFAM) systems. According to the company, other materials tested during the project could not provide the necessary melt strength, stiffness, and thermal stability required for the extreme angles. Credit: Airtech The printed pavilion was displayed on Florida International University’s campus throughout November 2024, serving as a research platform for exploring computational design, recycled composites, and LFAM workflows. The structure was subsequently showcased at ALCOVA 2025. The project demonstrates the capabilities of current 3-axis gantry systems when paired with appropriate materials for printing challenging geometries. The… read more

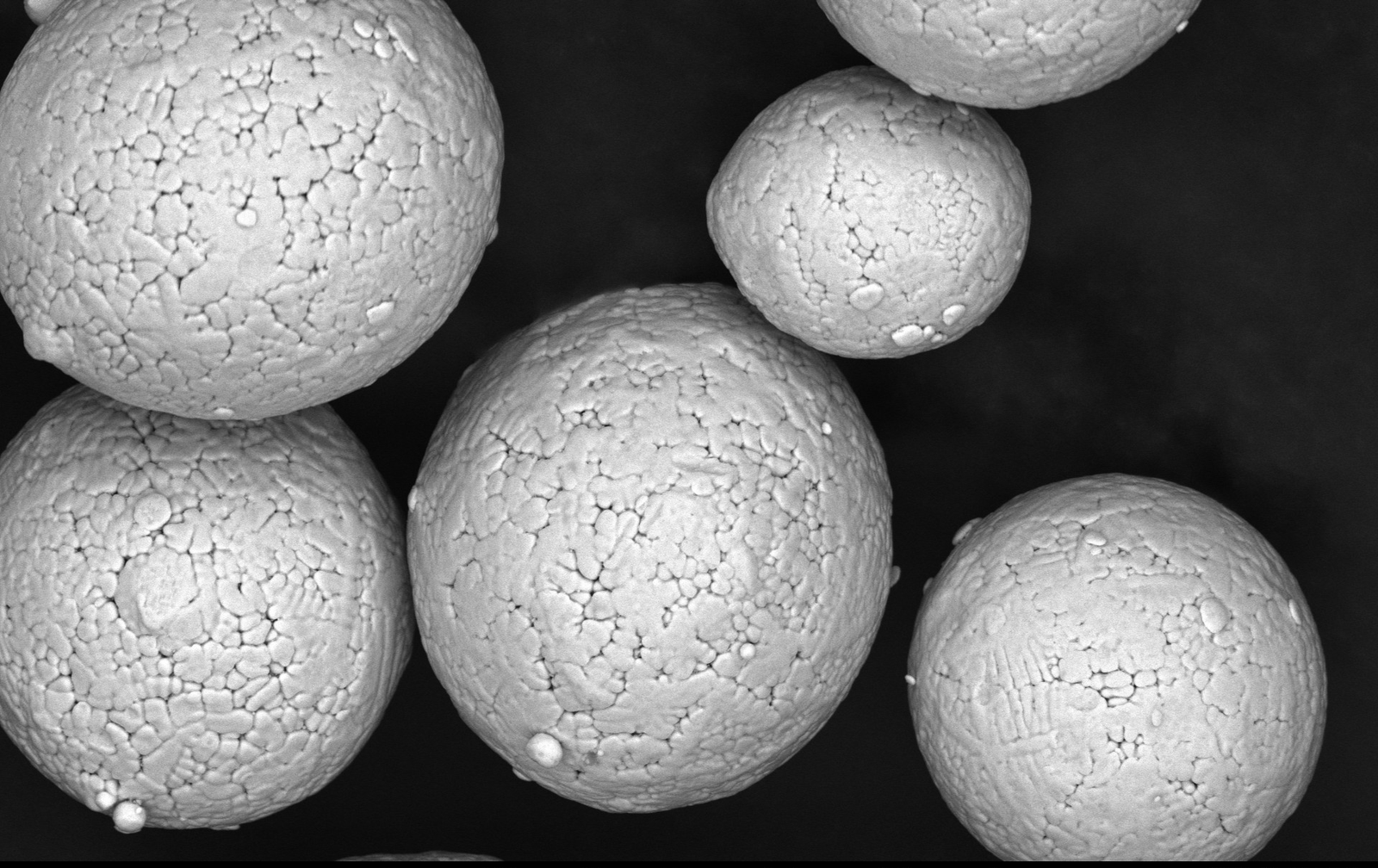

U.S.-based metal powder producer Continuum Powders has released two new copper-nickel alloy powders, OptiPowder C715 and OptiPowder C964, designed to perform reliably in challenging operating conditions. The powders deliver strong corrosion resistance, consistent thermal and electrical conductivity, and mechanical stability. Produced through the company’s proprietary Greyhound Melt-to-Powder (M2P) process using certified reclaimed feedstock, the alloys offer high performance while reducing environmental impact. Engineered for marine, energy, and industrial applications, these copper-nickel powders withstand seawater corrosion, stress-corrosion cracking, and erosion caused by high-velocity particles. Their uniform mechanical properties across a wide temperature range make them suitable for multiple additive manufacturing methods, including laser and electron beam powder bed fusion, binder jetting, hot isostatic pressing, direct energy deposition, and thermal spray processes. OptiPowder C71500. Image via Continuum Powders. Precision and Sustainability in Manufacturing The powders are produced with M2P atomization, converting reclaimed aerospace-grade metals into high-purity, spherical particles with consistent flow behavior…. read more

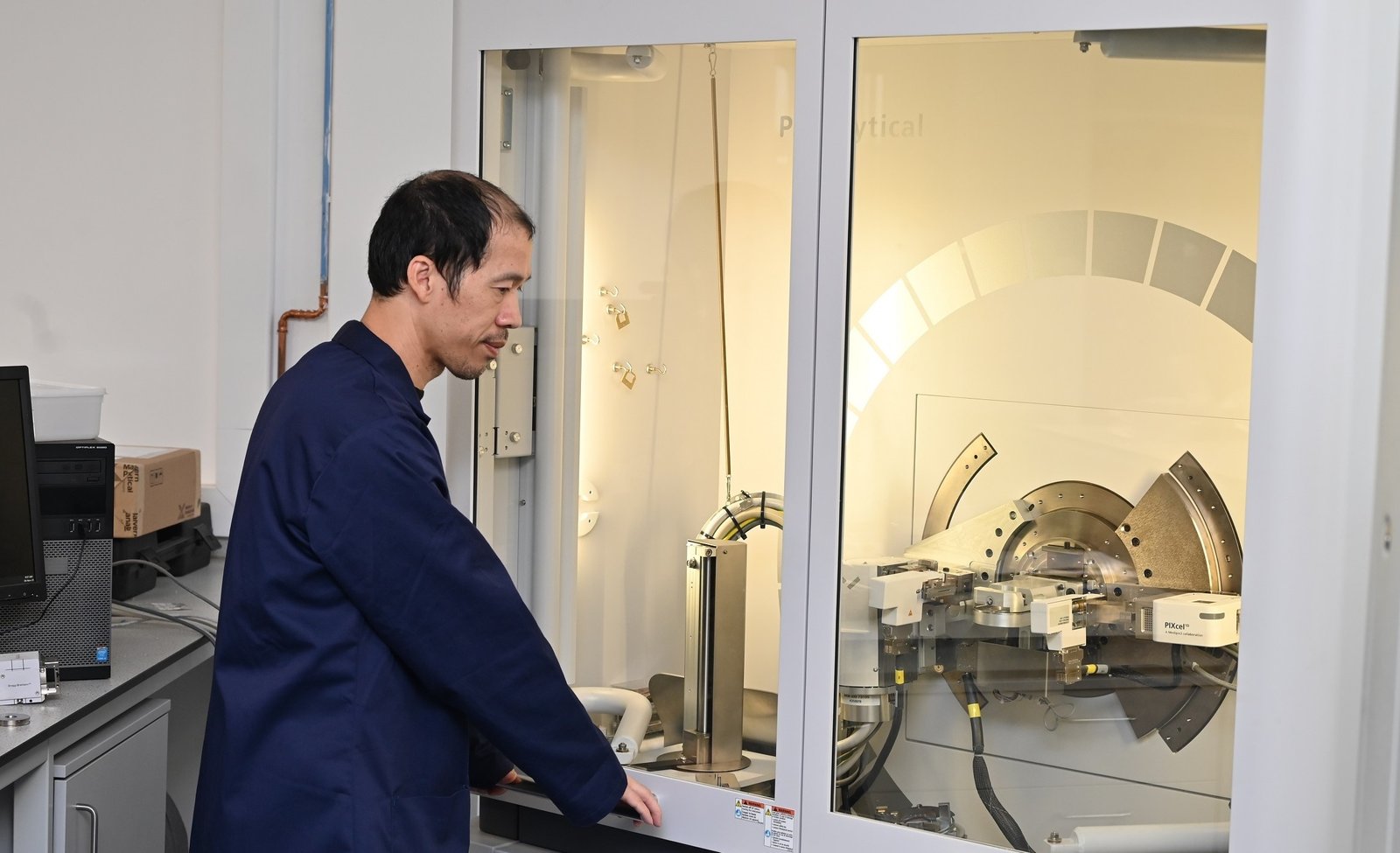

UK-based research organization Materials Processing Institute (MPI) has introduced a high-temperature X-ray Diffraction (XRD) system that allows researchers and industrial partners to study materials at temperatures up to 1600°C. This system enables real-time observation of phase transformations in ceramics, slags, minerals, and metal alloys under conditions relevant to industrial processes such as casting, kilns, and foundry operations. The capability has been implemented as part of the PRISM research programme, funded by Innovate UK, which supports innovation, productivity, and sustainability in the UK metals and steel sector as it transitions toward net-zero and circular-economy practices. High-Temperature Research Applications Demand for in-situ XRD analysis at temperatures up to 1600°C has been increasing, as both industry and academia seek to understand material behavior during heating and cooling cycles. MPI’s existing platinum hot stage XRD operates up to around 1400°C, but researchers in the Advanced Materials Characterisation Centre have designed a tantalum-based hot stage… read more