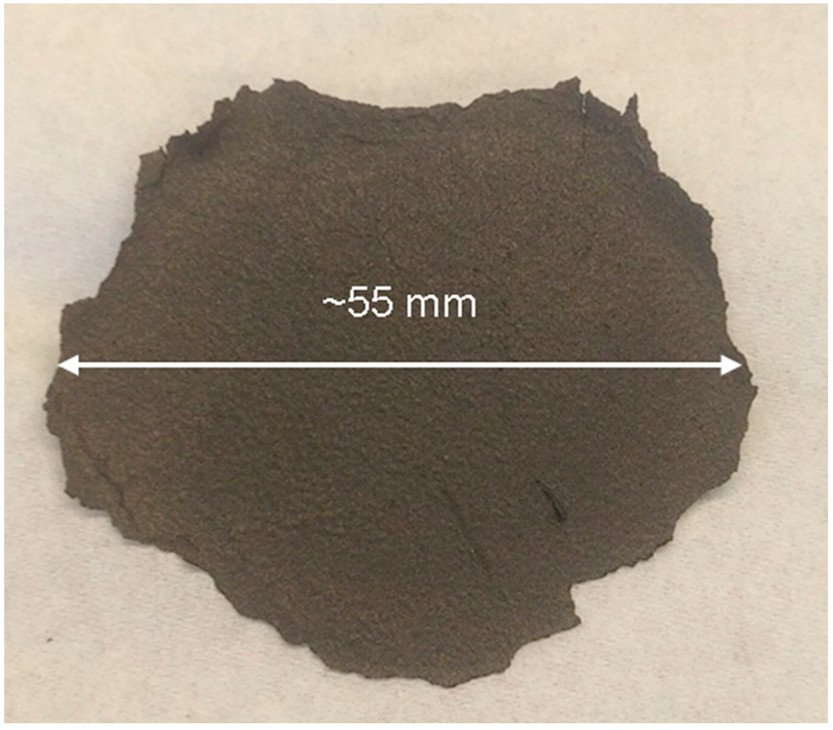

Researchers from Concordia University, Montreal, are exploring the 3D printing of graphene oxide liquid crystals to enable materials with previously-unseen levels of strength. Having made headlines for over a decade, graphene is one of those wonder materials that promised to solve a number of our engineering challenges. The sheet-form carbon allotrope comprises a single layer of atoms arranged in a 2D nanostructure resembling a honeycomb lattice. The material is known for its high strength-to-weight ratio, excellent thermal and electrical conductivity, corrosion resistance, and scratch-resistant qualities. Unfortunately, we haven’t yet been able to translate graphene’s strength from the microscale to real-world applications in the macroscale. The Concordia team is now using photocuring, the technology behind stereolithography 3D printing, to produce self-assembled graphene oxide structures that are both larger and more complex than today’s possibilities. A large graphene oxide sheet produced via photocuring, the process behind resin 3D printing. Photo via Concordia… read more

Alex

California and Arizona based battery company Ampcera Inc. has been awarded funds to develop 3D printed lithium-ion batteries. Ampcrea, along with partners at Lawrence Livermore National Laboratory (LLNL) have received $1.5 million USD in funding from the Department of Energy to develop a safer lithium battery with higher power and energy densities using a low-cost dry additive manufacturing process. Ampcera deals with the development and commercialization of high-performance solid-state electrolyte materials for next-generation lithium batteries. It is hoped that the partnership with the national laboratory will develop innovative manufacturing processes for lithium-ion batteries and reduce time-to-market. In addition, the process is apparently “environmentally benign” , which is why it is one of six Energy Systems projects selected for an award from DOE’s Advanced Manufacturing Office to reduce industrial emissions and manufacture clean energy technologies. The proposed dry additive manufacturing technology is highly energy-efficient with more than 10 times the throughput… read more

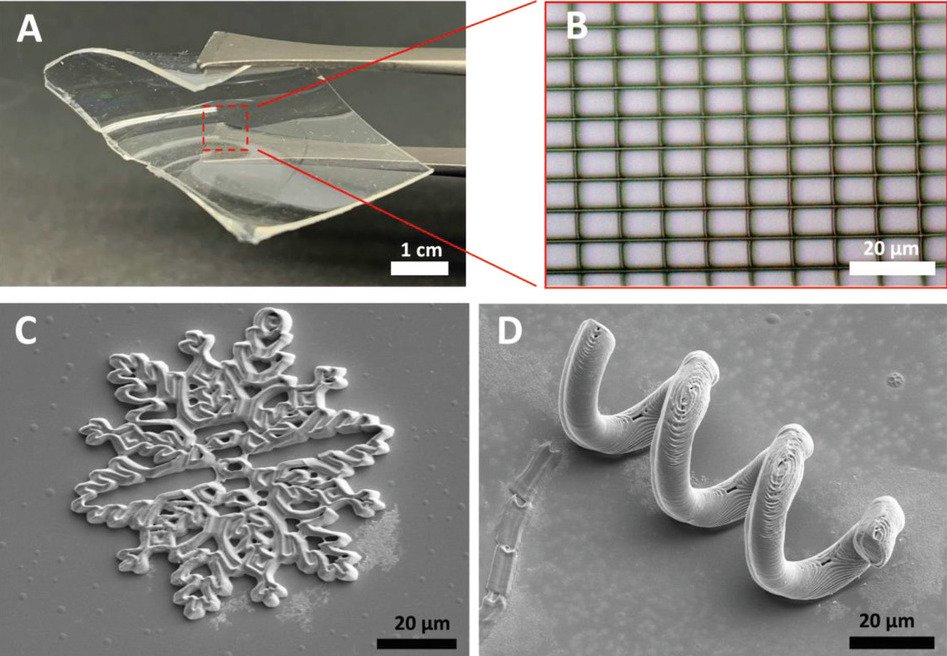

Scientists at the University of Houston have developed a novel method of 3D printing bio-sensors that could one day be implanted into human hosts. Using multiphoton lithography (MPL), the team’s approach involves polymerizing a resin loaded with an organic semiconductor material layer-by-layer, to form tiny, biocompatible circuit boards. Thus far, the researchers have utilized their process to create highly-accurate glucose sensors, but with further R&D, they believe it could pave the way for the production of a new generation of bio-electronic devices. “Here, a homogenous and transparent photosensitive resin doped with an organic semiconductor (OS) material is introduced to fabricate a variety of 3D OS composite microstructures (OSCM),” say the team in their paper. “[Our] results demonstrate the great potential of these devices for a wide range of applications from flexible bioelectronics, to nanoelectronics and organ-on-a-chip devices.” The researchers’ initial 3D printed microstructures. Image via the University of Houston. Bringing… read more

We have all read about so-called bioplastics. They are made from biological materials such as corn. Many bioplastics do not meet the requirements currently satisfied by oil-based commodity plastics such as PET though. PET, used extensively in plastic bottles, is valued for its low cost, ease of manufacture, and mechanical, thermal and chemical stability in a range of environments. These are all desirable features when manufacturing food-safe containers such as drinks bottles. Many bioplastics simply fail to live up to these requirements. In addition, not all bioplastics are as ecologically friendly as they are marketed to be. However, a new type of plastic made from biomass might be on the horizon thanks to a team of researchers from École Polytechnique Fédérale de Lausanne (EPFL) who have been producing stable yet degradable plastics from lignocellulose. Lignocellulose can come from non-edible plant matter and is the most abundant raw material on Earth… read more

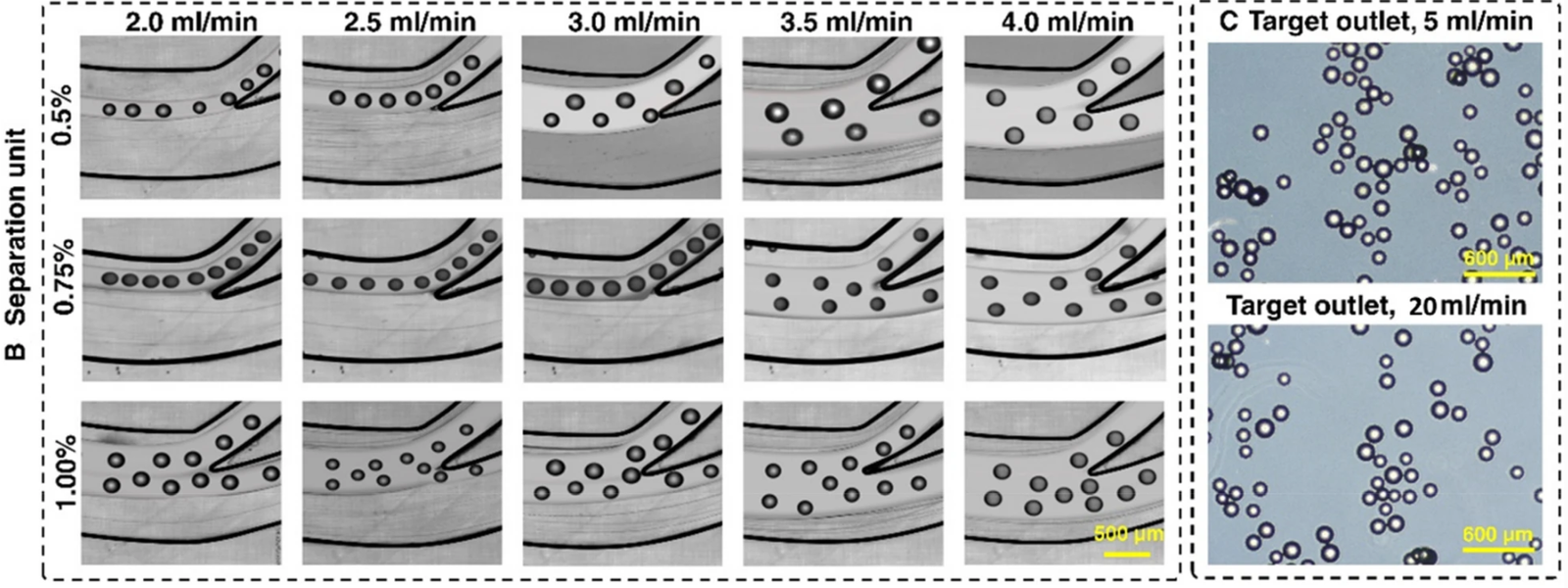

Researchers from the University of Technology Sydney (UTS), together with biotech firm Regeneus, have created what they claim is the world’s first 3D printed microfluidic device capable of harvesting stem cells. Bleeding-edge stem cell therapies are a promising way to treat a whole plethora of ailments, including arthritis, diabetes, and potentially even cancer. Stem cells work by differentiating into specialized cells, meaning they can be used to replace damaged cells around the human body. Unfortunately, harvesting and processing stem cells from donors is currently very time, cost, and labor intensive due to limitations in biotechnology. The 3D printed microfluidic device is designed to harvest stem cells from bioreactors, offering a scalable method of processing stem cells without the associated costs. Professor Majid Warkiani, the UTS biomedical engineer leading the research, said, “Our cutting-edge technology, which uses 3D printing and microfluidics to integrate a number of production steps into one device… read more