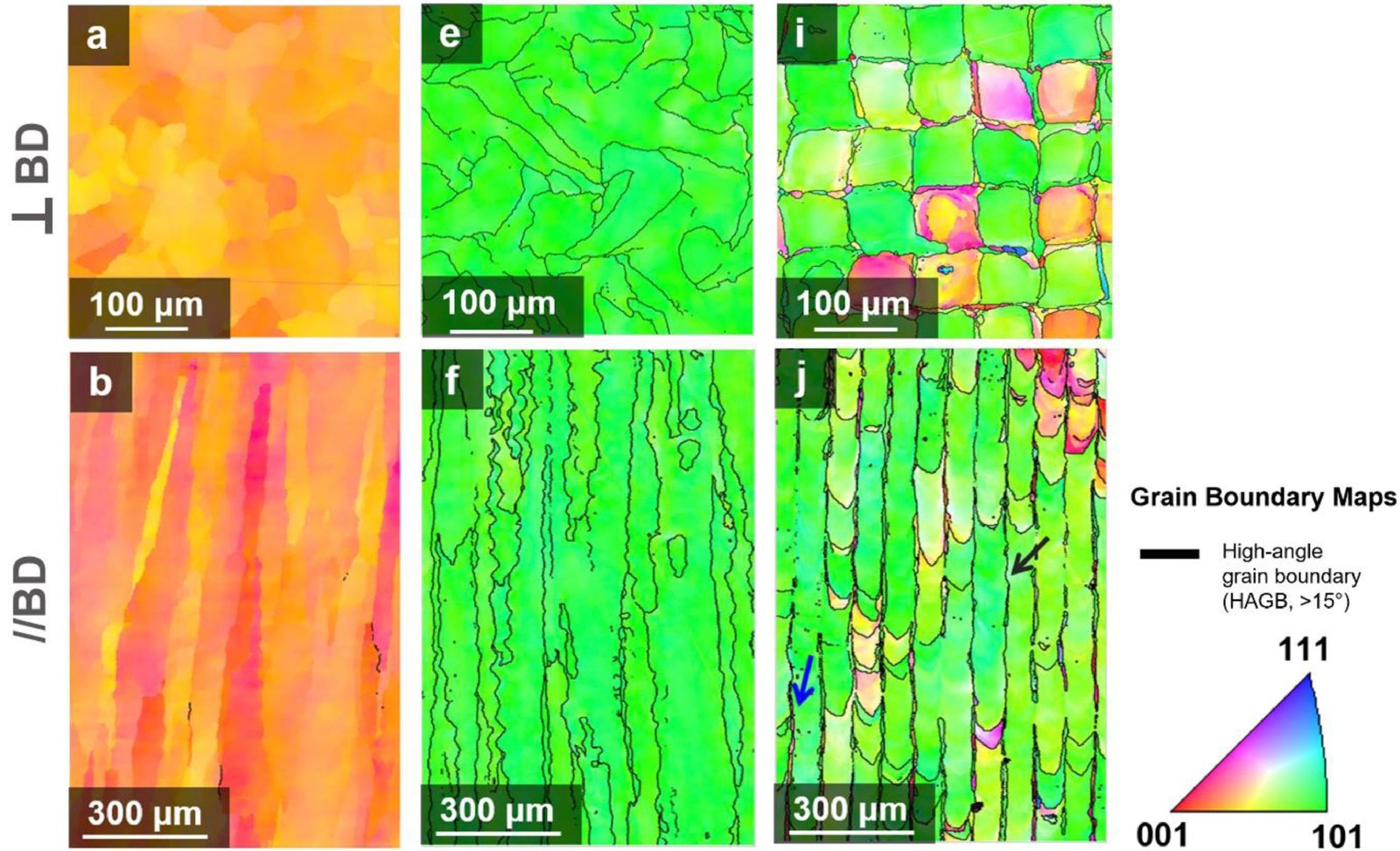

A team of Japan-based researchers is investigating the use of selective laser melting (SLM) technology to 3D print single crystal structures made of pure nickel (Ni). There’s been a growing demand for 3D printed Ni-based superalloys such as Inconel over the years. These high-temperature metals are often characterized by their excellent mechanical properties, corrosion resistance, and creep resistance, commonly operating in the 500°C+ temperature range. As such, they’re a go-to in the aerospace sector where they’re used to fabricate jet engine components like turbine blades. Single crystal turbine blades are capable of operating at much higher temperatures than their crystalline counterparts, but the additive manufacturing of Ni-based single crystal superalloys has proven difficult thus far. While they can be processed via electron beam melting (EBM), the use of laser-based technologies like SLM usually requires the use of a single crystal seed (build plate). Now, the team from Japan’s National Institute… read more

Alex

Engineers at UCLA have unveiled a new method of printing functional miniature robots that can be manufactured with a single printing process. The little fingernail-sized robots, dubbed meta-bots are printed with their mechanical and electrical systems complete, and this is achieved by use of piezoelectric metamaterials. Typically, piezoelectric actuation only has a single degree of freedom when a single crystal is used. However, by use of 3D printing, the engineers were able to not only increase the number of degrees of freedom allowing more complex movements, but were able to couple mechanical strain with electrical fields therefore allowing not only propulsion, but motion in multiple degrees of freedom, decision making, and the capacity for ultrasonic sensing also. The sensing capability is able to measure the movement in its own structure also, meaning that the robots have the ability for feedback control. You can see the tiny meta-bot in the image… read more

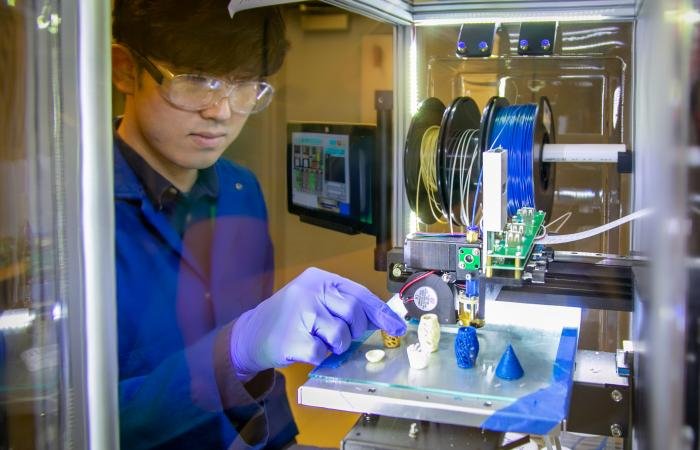

Researchers at Oak Ridge National Laboratory (ORNL) have come up with a novel way of turning discarded plastic into a Fused Filament Fabrication (FFF) 3D printing material. Using a ‘click chemistry’ reaction, the scientists’ method enables waste ABS to be turned into a ‘vitrimer,’ a polymer with the recyclability of thermoplastics and mechanical qualities of thermosets. According to the team, this “readily adoptable” process could serve as a basis for the introduction of “a closed-loop strategy,” that reduces the need for new plastics and cuts emissions tied to their production. “We will need fundamental discoveries to overcome the challenges of increased costs and deteriorating material properties associated with recycling,” said lead author Tomonori Saito of ORNL’s Chemical Sciences Division. “Our goal was to develop an easily adoptable strategy that reuses plastic waste to create a more valuable material instead of generating fresh plastic.” The ORNL’s Sungjin Kim 3D printing using… read more

3D scanner manufacturer Revopoint has launched its latest 3D scanning system on Kickstarter. Aimed at both consumers and professionals, the new space-efficient Revopoint MINI is the company’s first machine based on structured blue light technology. The full-color scanner is designed to combine performance and affordability, ensuring anyone and everyone can capture the finest feature details in their 3D scanning projects. Compared to Revopoint’s flagship POP 2 scanner, the new MINI offers a smaller capture range and a higher scan precision of just 0.02mm. This makes it suitable for a wide variety of small part scanning applications with tight precision requirements, including reverse engineering, dental modeling, jewelry, industrial quality control, and 3D printing. Scanning artistic models with the Revopoint MINI. GIF via Revopoint. The Revopoint MINI The Revopoint MINI is defined by its ease of use and simplicity, offering a compact form factor weighing just 160g. Manufactured out of die-cast aluminum,… read more

The results of the State of Resin 3D Printing survey are in. Working with Henkel, we asked readers a range of questions, from the applications and technology they are working with to levels of satisfaction with materials and the most influential factors on a purchase decision. Alongside the survey, we also conducted a series of interviews with experts in the resin 3D printing world. You can read the series here. About the data The survey was conducted in March 2022, and the final sample size was 198. Almost a quarter of responders (22%) who use 3D printing said they were familiar with Henkel’s Loctite resin portfolio. For this group who were not currently using Loctite 3D printing materials, nearly half (49%) said they would consider using them in the future. The users of resin 3D printing classified themselves according to their usage of the technology at the following levels: Low… read more