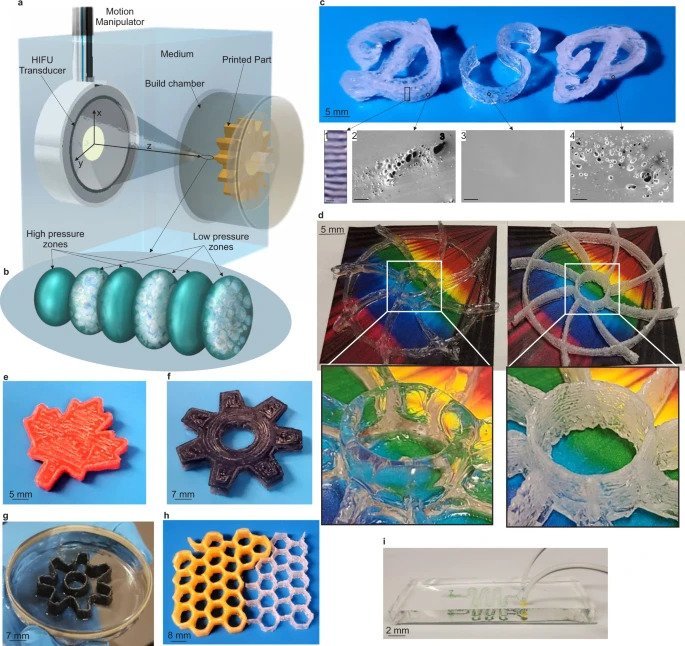

Researchers from Concordia University have developed a novel direct sound printing (DSP) technique that leverages ultrasound waves to fabricate complex and precise objects. The team has published a paper describing the technology, which works by using sound waves to create sonochemical reactions in minuscule cavities to produce pre-designed complex geometries that cannot be achieved with existing techniques. “Ultrasonic frequencies are already being used in destructive procedures like laser ablation of tissues and tumors,” said Muthukumaran Packirisamy, a Professor in Concordia’s Department of Mechanical, Industrial and Aerospace Engineering. “We wanted to use them to create something.” Ultrasonic 3D printing The use of ultrasound in microparticle manipulation is not a new concept, with ultrasonic waves having proven to be a useful tool across multiple areas of 3D printing in the past. The last few years have seen researchers from the University of Bath and the University of Bristol develop their Sonolithography bioprinting… read more

Alex

The Halot-One series of resin printers from Creality offers high quality resin printing at a price friendly to most makers and 3D printing fans. At the core of the Creality Halot-One lies the Integral Light Source technology, which helps users create perfect prints. But what is the Integral Light Source and exactly how does it help keep print quality high? Read on to know more! Halot One Series The Halot One resin printer series was first released in 2021 with the original Halot-One. Since then the range has expanded to include new models including the original Halot-One, Halot-One Lite, Halot-Sky and most recently, the Halot-One Plus and Halot-One Pro. Halo there! The Halot-One Plus, and the Halot-One Pro (Image credit: Creality) The printers in the series all vary in size, but all of them have the Integral Light Source technology at their core. Most budget resin printers make use of… read more

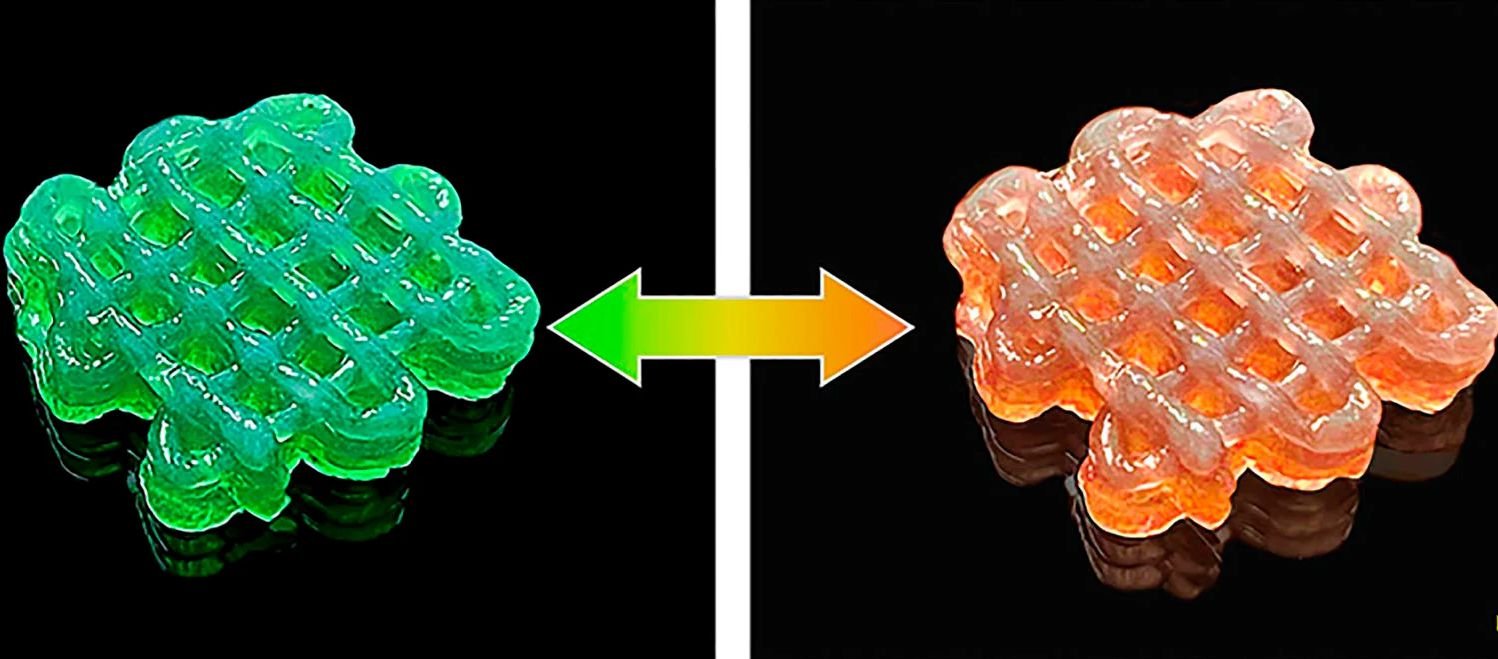

A group of China-based researchers have developed a new way of adding color to 3D printed parts that’s said to result in much safer products than conventional dyeing or pigmentation. The scientists’ approach revolves around a biocompatible ink they’ve developed, which yields parts capable of changing appearance through ‘structural coloration,’ in response to heat or light stimuli. Using their material, the team say it could be possible to produce everything from wearable bio-sensors to more child-safe toys. “We believe that [our] cholesteric liquid crystal ink can shed light on next-generation environmentally friendly 3D photonic printing,” the team explain in their paper, published in this week’s Proceedings Of The National Academy Of Sciences journal. “The ink maintains a cholesteric liquid crystalline state that gives rise to the structural color.” A 3D printed part changing color under different thermal conditions. Image via the South China Morning post. Overcoming the toxicity of dyeing… read more

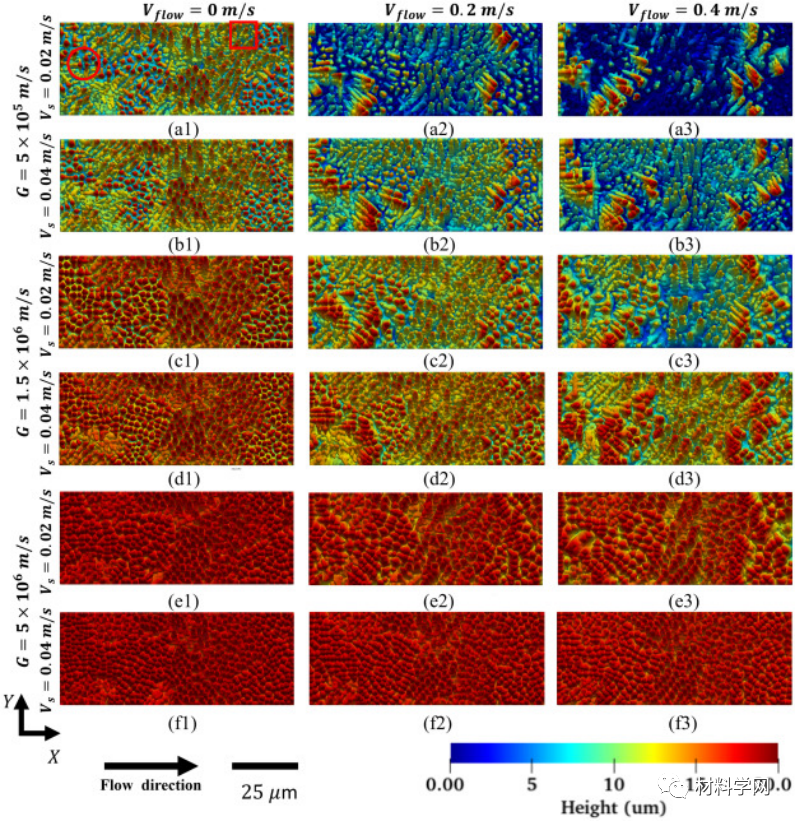

Researchers from Tsinghua University and the National University of Singapore are investigating the effects of fluid flow on the mechanical properties of metal 3D printed parts. When it comes to metal additive manufacturing technologies like laser powder bed fusion, carefully controlling the formation of new grains and dendrites in printed parts is crucial for tuning the final grain structure. This is important because grain structure and grain size have a significant effect on almost all mechanical properties, including hardness, yield strength, tensile strength, fatigue strength, and impact strength. There are a whole host of factors and parameters that can influence the formation of new grains and dendrites in 3D printing, but temperature gradient and solidification velocity are already thought to be prime determinants. According to the researchers however, the effects of fluid flow in the melt pool of a 3D printed part haven’t yet been investigated. SEM imaging of a… read more

The shipbuilding process, like aerospace development, often requires the construction of scale models of the vehicle in question in order to validate certain aspects of the design before splashing out on a full scale manufactured product. You have seen this with aircraft in wind tunnels, where the geometric model is used to represent the aerodynamic surfaces on an aircraft in flight. Similarly, ship models of various scales are used for a variety of fluid dynamic analyses in various fluid testing facilities. With ships, the models can take around 3 weeks to build out of wood, which is typically carved up via CNC. South Korean shipbuilder Daewoo Shipbuilding & Marine Engineering Co. has teamed up with Ingersoll to utilize thermoplastic additive manufacturing to produce these models, resulting in a 40 percent reduction in build time. You see the 10-meter long ABS model being printed in the image below. ABS ship scale… read more