Material manufacturer Epson Atmix Co (Atmix), subsidiary of the multinational Japanese electronics firm Seiko Epson Corporation (Epson), has unveiled plans to establish a new metal powder factory. Set to open by 2025, the complex is expected to feature metal recycling facilities, that enable scrap materials to be turned into usable alloy powders with 3D printing potential. Atmix’s announcement closely follows Epson’s own revelation that it plans to finally enter the additive manufacturing sector with a new industrial extrusion 3D printer, some eight years after first signaling its intention to do so. Atmix’s Kita-Inter Plant. Image via Epson. Epson finally segues into 3D printing Although Epson is primarily known for its 2D printing exploits, it has made no secret of its aspiration to expand into the 3D printing industry. As long ago as 2014, the firm’s President Minoru Usui talked openly of wanting to move into 3D printing, not just with… read more

Alex

April 25, 2022 Leave a Comment Additive manufacturing offers a number of benefits to those wishing to develop antennas in various non-traditional geometries, and a team of researchers in the US have recently test-flown a drone with a printed antenna to demonstrate those benefits. Ohio-based drone company Event38 have been working with local partners (Ohio Federal Research Network (OFRN), Kent State University, Youngstown State University, and Youngstown Business Incubator (YBI)) to upgrade their E400 mapping drone with a new hybrid antenna/nose cone. The part was printed with a combination of metal and polymer printing, and was presumably assembled afterwards into a single unit. E400 drone. (Image credit: Event38) Typically antennas need to be conductive, but as we have seen in previous articles, it is perfectly possible to print complex geometries in plastics and apply conductive materials to them after printing. This is a lot more cost effective than simply printing… read more

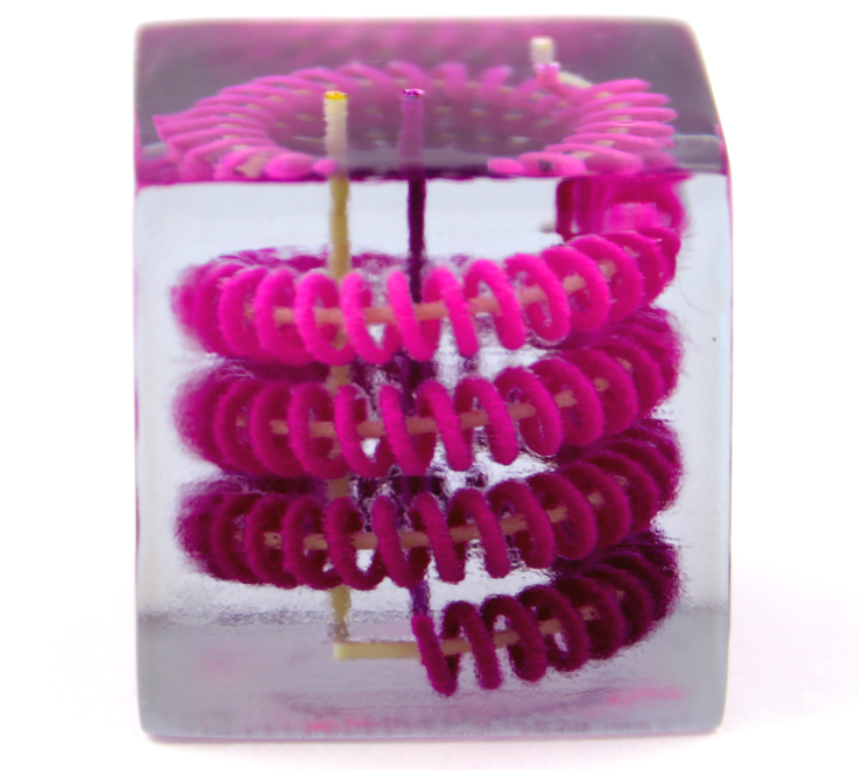

Researchers from the University of Colorado Boulder have developed a new method of multi-material 3D printing that’s capable of producing parts with both solid and liquid components. Virtually all of today’s 3D printers, bar maybe a few experimental devices, 3D print exclusively solid objects. This is great for everything from desk toys and gears to engine parts and electronics casings, but the ability to integrate liquid sections into a build could vastly expand the number of potential applications. For example, a solid-liquid printer could fabricate entire wearable electronics with solid structural parts and integrated liquid wires, as well as lifelike medical models that more accurately mimic the look and feel of human organs. Taking it a step further, such a machine might even be able to produce an entire print-in-place robot with a single print run, eliminating the need for any assembly. Robert MacCurdy, senior author of the study, said,… read more

April 26, 2022 Leave a Comment Oh, how times change! If you had tried to make a small plastic electric vehicle 35 years ago, you would have been pilloried and mocked relentlessly. Just ask home computer pioneer Sir Clive Sinclair, who in 1985 released his Sinclair C5 e-trike and got that exact same response. It seemed that some folks had issues with sitting in a battery/pedal powered recumbent tricycle with truck wheels roaring by at mere inches from their petrified heads… While the C5 debacle buried the idea of actually useful urban EV products for decades, the idea of small, fuel efficient concepts has been kept alive and kicking in the Shell Eco-marathon. The marathon has been running for many years now and has been used as a platform for student teams to push the envelope in terms of fuel economy, and this year a team from Saskatchewan Polytechnic has… read more

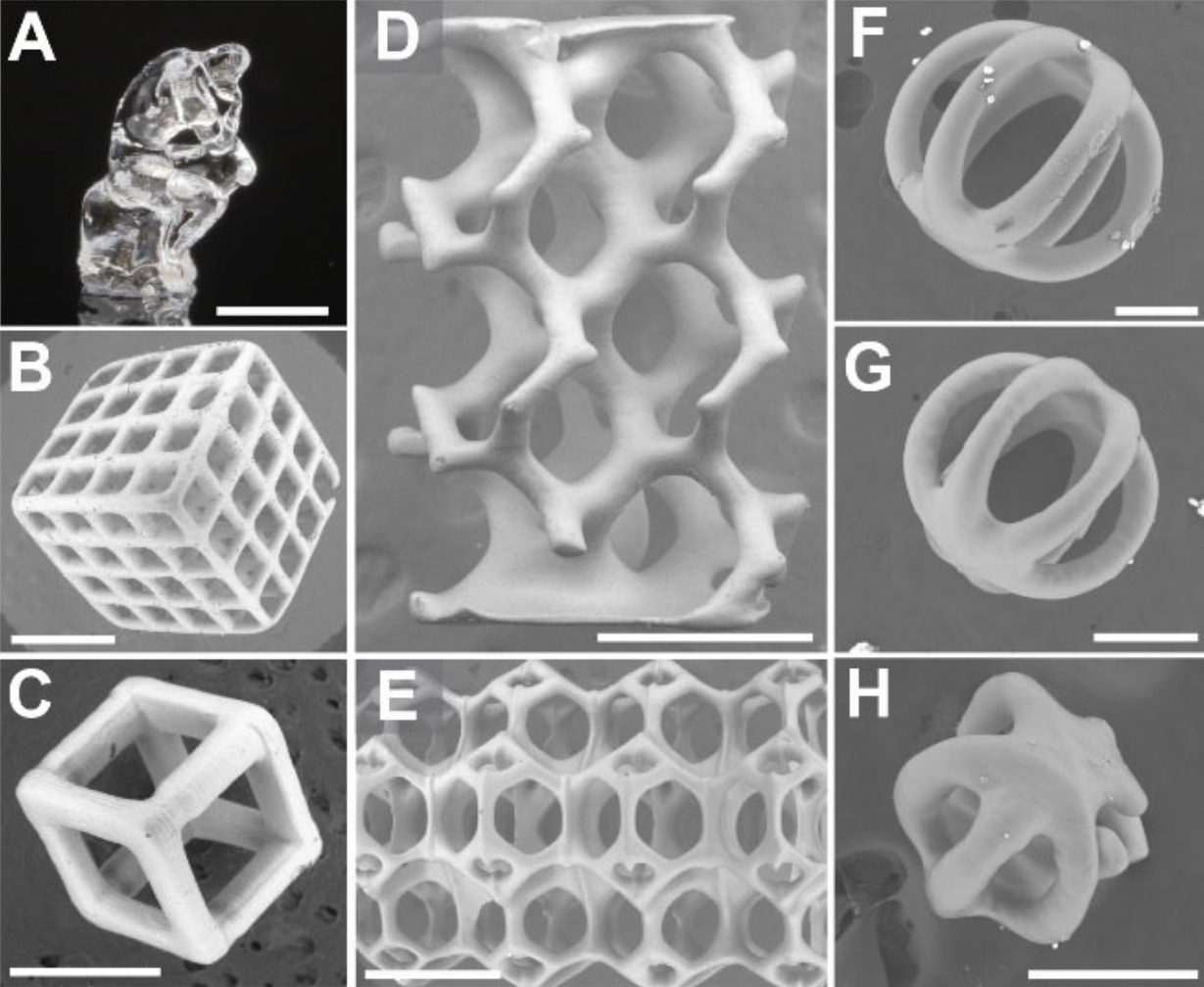

Researchers at the University of Freiburg have worked with colleagues at the University of California, Berkeley to come up with a novel means of rapidly 3D printing complex glass parts at a microscopic scale. Known as ‘ Microscale Computed Axial Lithography’ (Micro-CAL), this approach involves exposing resin to 2D light images of a desired shape from multiple angles, which when they overlap, trigger polymerization. When used to print the Glassomer material previously honed at Freiburg, the team say their layer-free process has the potential to unlock devices with new microfluidic or micro-optical functionality. “For the first time, we were able to print glass with structures in the range of 50 micrometers in just a few minutes, which corresponds roughly to the thickness of a hair,” explains the University of Freiburg’s Dr. Frederik Kotz-Helmer. The ability to manufacture such components at high speed and with great geometric freedom will enable new… read more