The US Department of Defense (DoD) has awarded Georgia Tech with two 2022 Multidisciplinary University Research Initiative (MURI) awards totaling around $14 million. One of the projects, titled Programming Multistable Origami and Kirigami Structures via Topological Design, looks at how principles from the art of paper folding can be used in conjunction with 3D printing to design lightweight and flexible structures capable of changing shape. The aim is to enable structures that can transition between a wide variety of stable geometries to perform specific actions or adapt to ever-changing environmental conditions. The work is expected to have applications in everything from 3D printed multifunctional robotics to morphing bridges and collapsible radiofrequency components such as antennae. Georgia Tech campus. Photo via Georgia Tech. The MURI awards MURIs are awarded as part of a highly competitive DoD program designed to support teams of researchers that conduct work that may one day be… read more

Alex

April 20, 2022 Leave a Comment Learn how to set up a school’s 3D print program successfully and enjoy one of the most rewarding experiences in education. Watch students get deeply engaged in their learning process – across geography, chemistry, biology and more! Keys to set up a school’s 3D print program To successfully set up a school’s 3D print program one does depend on a few things, of course.Students need to enjoy success and at the same time – admins need to manage print queues without spending crazy amounts of time doing so!These are 3 critical indicators of a school’s 3D print program success. Indicator 1: Increased 3D Print Success One piece of prime importance is optimizing everything for more successful prints.On the one hand, you want students to push their own boundaries and accept that in doing so, they will sometimes fail. However, on the other hand, you… read more

In the second edition of 3D Printing Industry’s series on Artificial Intelligence (AI) and 3D printing, interviewees tell us how the technology is helping step up the process of identifying, optimizing and qualifying new additive manufacturing materials. As engineers that work in the industry will no doubt be aware, before 3D printing with any novel material, it’s necessary to ‘qualify’ it first. Traditionally, this has meant identifying a link between entered parameters for processing a given feedstock, and the properties of the parts it produces, in a way that provides later users with assurances on quality. However, qualification can be lengthy and laborious, and in the past, the National Institute of Standards and Technology (NIST) has criticized its “lack of repeatable process outcomes,” as an “impediment to [3D printing’s] widespread implementation.” One of those now seeking to accelerate the process is Intellegens, which has developed its own AI toolset that’s… read more

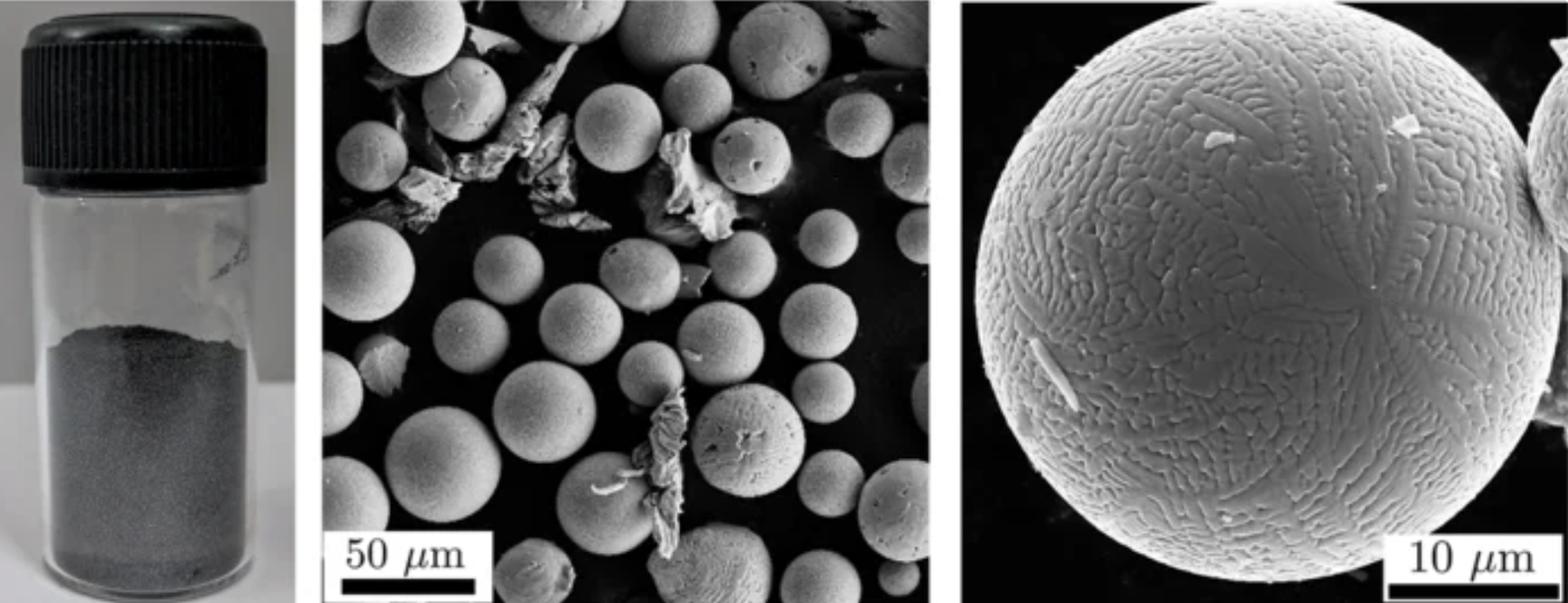

Researchers from the Indian Institute of Science (IISc) have developed a new abrasion-based method of producing metal powders for 3D printing. The approach is designed to provide an alternative to atomization, the technique by which most metal powders are currently produced. In atomization, a gas or water jet is used to break up a molten stream of metal into tiny droplets, which form powder particles once cooled. Unfortunately, despite it being the gold standard in the industry, atomization-based powder production can suffer from poor material yield, it can be cost-inefficient, and it’s only compatible with a limited number of metals. The IISc approach aims to address these shortcomings. Priti Ranjan Panda, a Ph.D. student at IISc’s Centre for Product Design and Manufacturing, said, “We have an alternative, more economical and inherently scalable route for making metal powders, and the quality of the final powders appear to be very competitive when… read more

April 15, 2022 Leave a Comment Construction additive manufacturing is still seeking new ways to demonstrate its value, and as we saw a few weeks ago with the printed flood relief housing, it is finding more and more use in transient housing applications. Well, it could be said that there are none more transient than soldiers in training, and so the US Department of Defense has employed Texas-based construction printer company ICON to print their vast barracks complex at Fort Bliss, Texas. There will be three barracks printed at the facility, each housing up to 72 soldiers at a time. At approximately 530 square meters of area each, they will be the largest 3D printed structures in the western hemisphere. The current world’s largest AM structure is in Dubai, as we reported here. That was printed by Apis Cor with their concrete printing systems. You can see a rendering of… read more