Surface treatment specialist FerroECOBlast, together with the Jožef Stefan Institute (Slovenia) and Joanneum Research Centre (Austria), has investigated the effects of shot peening on the fatigue strength of metal 3D printed parts. Surface treatments are an important part of the 3D printing workflow and often happen in the post-processing phase after a build is complete. There are a wide variety of surface treatments available today, each with its own use case. For example, there are treatments for smoothing out part surfaces, boosting mechanical properties like strength, and increasing durability by way of wear, corrosion, or heat resistance. Shot peening, otherwise known as cold micro-forging, is one such surface treatment. Often used on metal parts in critical industries like aerospace or automotive, shot peening works by striking a surface with a granular ‘shot’ material (blast media) to produce a compressive residual stress layer and enhance the mechanical strength of a part…. read more

Alex

March 14, 2022 Leave a Comment 3D printed products that you can put inside your ear are not a new thing. The majority of hearing aid devices have been 3D printed for years. Indeed beyond the world of custom medical devices, headphone manufacturers such as Sennheiser have already been experimenting with printed plastic headphones for a while now. But has anyone used space-grade amorphous alloys in a set of printed headphones? They have now. Image Credit: Sennheiser Furthering their ventures into 3D printed headphone products, Sennheiser has recently released their printed metal in-ear headphone (named as “IE 600”), which has been printed with a zirconium-based amorphous alloy. This same alloy is currently being used on Mars where it is being used as the drill head on the Mars Perseverance rover. This particular alloy is prized for its strength, elasticity, biocompatibility and corrosion resistance. The amorphous nature of the metal allows… read more

Thermoplastics materials developer UBQ Materials has won the Speculative Design category at the 24th annual South by Southwest (SXSW) Innovation Awards for its waste-based 3D printing filament. The material is the first waste-based 3D printing material made with UBQ, the company’s ‘climate positive’ thermoplastic, which was designed to enable additive manufacturing with a significantly reduced carbon footprint. “3D printing enables manufacturers across industries the option to design complex products with near immediate customizations that otherwise might be impossible to produce using conventional manufacturing methods,” said Tato Bigo, Co-CEO and Co-founder of UBQ Materials. “The use of UBQ in the printing filament offers manufacturers the ability to gain the benefits of 3D printing, while capitalizing on the reduced carbon footprint enabled by UBQ.” UBQ Materials has won the 2022 SXSW Innovation Award for Speculative Design. Photo via UBQ Materials. Converting waste into thermoplastics UBQ Materials has developed a patented advanced conversion… read more

March 19, 2022 Leave a Comment Modix, the Israeli printer company known for building fairly big and sturdy machines at very reasonable prices has got some new hardware and features out, and have released a couple of videos to show them in action. So let’s take a look. Griffin Print Head The Modix printers are set in a steel frame, making it a sturdy and reliable platform for those precision linear rails upon which everything moving rests. So with all this rigidity abound, you probably want an equally sturdy print head, right? Similar to the previous print head / structure found on Modix printers, this is made from bent steel sheets forming a totally rigid enclosure. Inside the structure sits a new extruder designed in collaboration with Bondtech, and also a custom hotend, designed with Slice Engineering. The design includes the advanced Slice Engineering Bi-Metal heat-break that extends the melting… read more

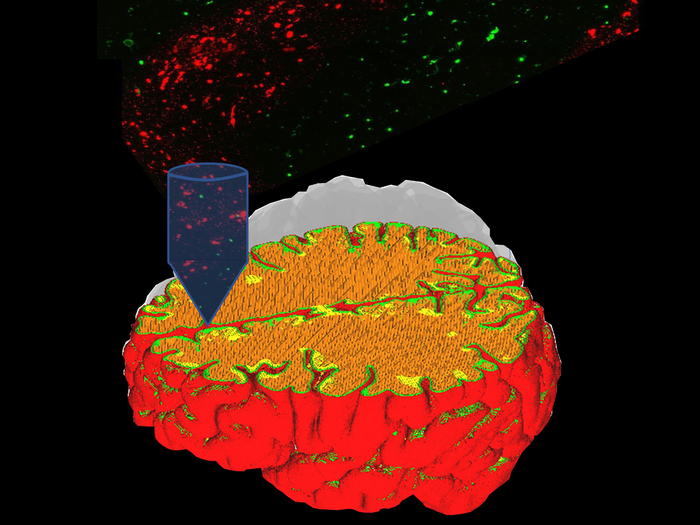

Researchers from Politecnico di Milano and Humanitas University are investigating the causes and development of neural diseases like Pitt-Hopkins syndrome (PTHS) using 3D printed neural tissues. The project has been granted €250,000 by Fondazione Cariplo as part of a call for projects under the banner “Biomedical research conducted by young researchers 2021”, and involves creating an in vitro model of the human cerebral cortex with 3D bioprinted vascularized neural tissues. “Our final objective is to lay the foundations to understand the various diseases that affect neural development in order to favor the identification of therapeutic strategies,” said Mattia Sponchioni of Politecnico di Milano and project coordinator. “This has been unthinkable to date.” Schematic representation of the project objective: to create a 3D model of the cerebral cortex by 3D bioprinting of cells derived from cortical organoids. Image via Politecnico di Milano. Investigating the causes of PTHS PTHS is a rare… read more