The Fraunhofer Institute for Laser Technology (ILT) and German machine tool manufacturer TRUMPF have signed a cooperation agreement to accelerate the transfer of technology to industry within the field of laser metal deposition. The partners will combine their respective expertise in laser system technologies and application-specific know-how to carry out research and development into improving the productivity, speed, materials, and processes of laser material deposition for their customers. “Our core business is developing application-adapted processes and system technology components,” said Dr Thomas Schopphoven, Head of the Laser Material Deposition Competence Area at Fraunhofer ILT. “The basis for this is our 30 years of experience in laser material deposition – in applications we have developed for a wide variety of industries. “When we transfer our technologies to industrial applications, our customers are increasingly focusing on the questions of systems engineering implementation, especially with regard to the availability, stability, and suitability of… read more

Alex

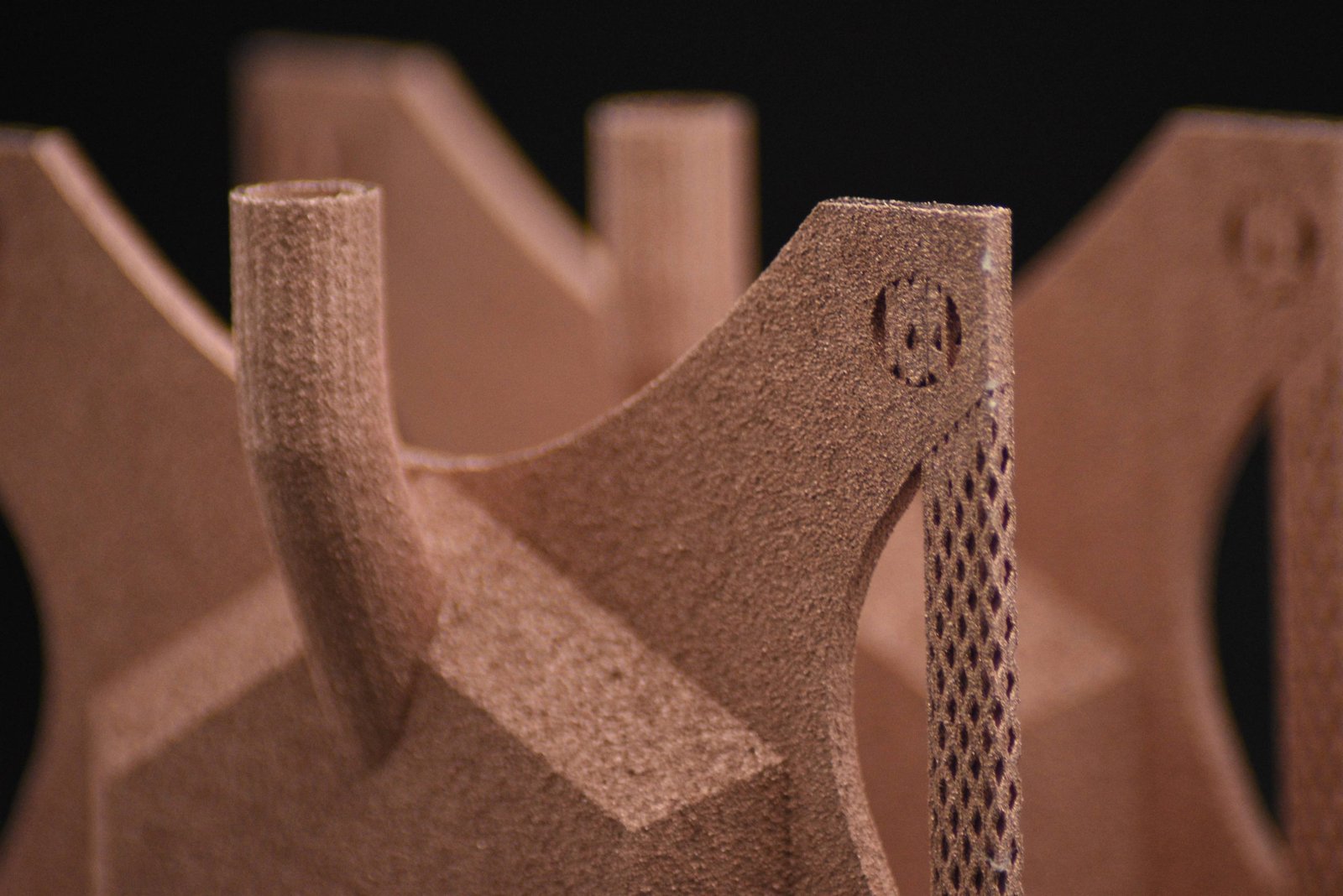

The past month has yielded several announcements from the copper 3D printing sector. Infinite Flex, a Germany-based developer of smart materials, recently launched what it claims to be the world’s first pure copper powder for SLM 3D printing. Dubbed INFINITE POWDER Cu 01, the material has already been successfully tested on a number of standard SLM 3D printers such as the EOS M290 and Trumpf TruPrint 1000, and is now commercially available. Elsewhere, UK-based alloy design firm Alloyed recently showcased its latest copper 3D printing application – a highly optimized cooling plate for use in high-performance temperature regulation applications. Michael Holmes, MD at Alloyed, said, “The cooling plate is a great example of what can be done when optimized AM geometry is combined with optimized AM material properties.” Alloyed’s 3D printed copper cooling plate. Photo via Alloyed. Infinite Flex’s INFINITE POWDER Cu 01 Pure copper is well known for its… read more

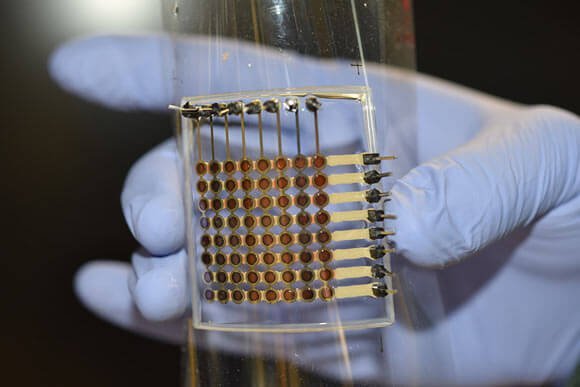

January 13, 2022 Leave a Comment OLEDs are traditionally manufactured using multiple substrates of various materials. The light comes from the emissive layer, which exchanges electrons for photons to produce light. The color of the light depends on the type of organic molecule in the emissive layer. Typically they are manufactured by various deposition processes and use inkjet printing to add the organic layers between the anode and the cathode before a final piece of glass or plastic is applied to complete the OLED display. If that sounds like a bit of a chore, then you are absolutely correct. That is why OLEDs are expensive devices. But a team of researchers from University of Minnesota Twin Cities have recently published a means to 3D print OLED panels, which could open the way for OLED panels to be manufactured in the home. You can see the 64 pixel (hand for scale)… read more

October 26, 2021 Leave a Comment Dresden-based motorbike company Hookie has recently revealed a concept for a Moon bike, which features 3D printed polymer wheels. The bike is named Tardigrade, after the small creature famed for its ability to survive the hard vacuum and radiation environment of space. According to the Hookie website, the bike was named as such because “Tardigrades are true survivors who have also endured the rigors of outer space.”, and we guess the bike can do the same. And this is what it looks like: The Tardigrade bike (Image credit: Hookie) The bike is fully electric, obviously, because you’d have difficulty running an internal combustion engine on the Moon, with the lack of oxygen (and gas stations) and whatnot. In terms of other stats, the concept bike measures 2.6 metres in length, has a range of 110km, a top speed of 15km/h and a weight of… read more

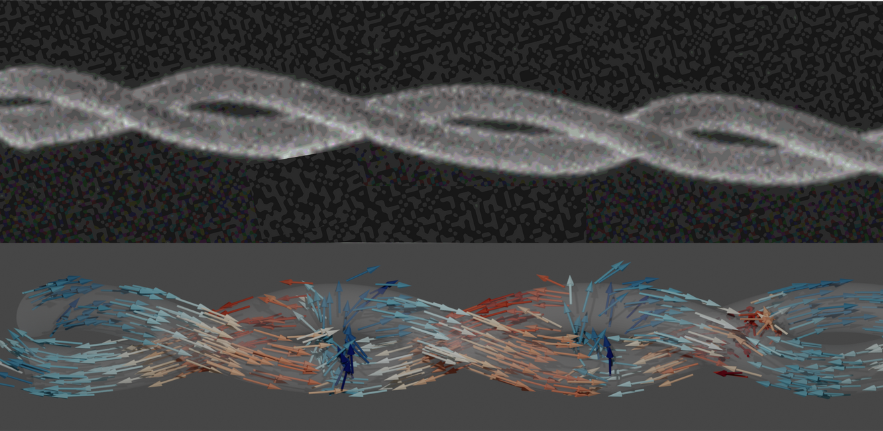

An international team of scientists led by Cambridge University’s Cavendish Laboratory has used 3D printing technology to develop a novel set of microscopic nanomagnets. Created using a custom 3D printing process, the nanomagnets are in the shape of a DNA-inspired double helix. According to the research team, this unconventional structure lends itself to strong magnetic field interactions between the helices in a manner never seen before. Specifically, by twisting around one another, the 3D printed helices produce nanoscale topological textures in the magnetic field they generate. The team believes it can harness this phenomenon to closely control magnetic forces at the nanoscale, paving the way for ‘next generation’ magnetic devices. Claire Donnelly, first author of the study, explains, “This new ability to pattern the magnetic field at this length scale allows us to define what forces will be applied to magnetic materials and to understand how far we can go… read more