The results of the State of Resin 3D Printing survey are in. Working with Henkel, we asked readers a range of questions, from the applications and technology they are working with to levels of satisfaction with materials and the most influential factors on a purchase decision. Alongside the survey, we also conducted a series of interviews with experts in the resin 3D printing world. You can read the series here. About the data The survey was conducted in March 2022, and the final sample size was 198. Almost a quarter of responders (22%) who use 3D printing said they were familiar with Henkel’s Loctite resin portfolio. For this group who were not currently using Loctite 3D printing materials, nearly half (49%) said they would consider using them in the future. The users of resin 3D printing classified themselves according to their usage of the technology at the following levels: Low… read more

Our Blog

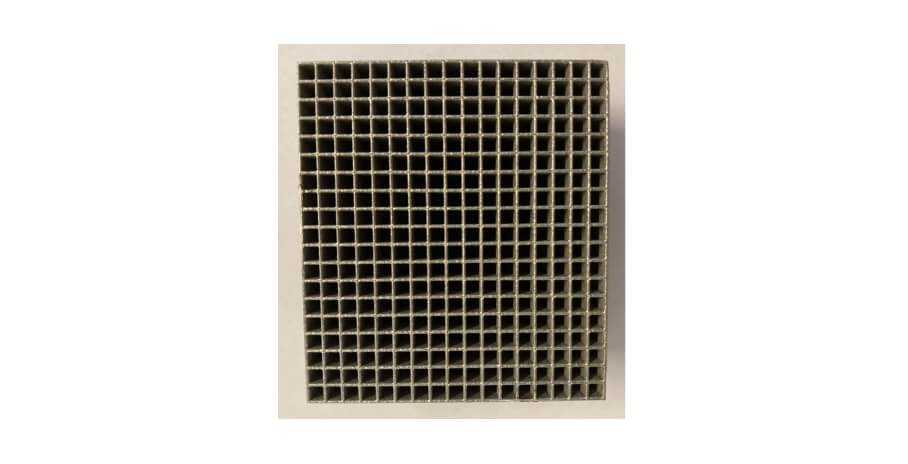

Power company Westinghouse has announced that they have installed two 3D printed nuclear fuel debris filters in nuclear power plants in both Finland and Sweden. The 3D-printed nuclear fuel debris filter, dubbed the “StrongHold AM” has been installed in two Nordic Boiling Water Reactor (BWR) units. The first is installed at the Olkiluoto Nuclear Power Plant in Finland, specifically in the Olkiluoto 2 unit. The second StrongHold AM fuel debris filter has been installed in Finland, and at Oskarshamn Nuclear Power Plant in Sweden (specifically Oskarshamn unit 3). The fuel debris filters will improve the reliability of both nuclear plants. You can see the debris filter in the image below. Debris filter. (Image credit: Westinghouse) While the name may suggest that this is a filter that filters fuel (like a car fuel filter), it is in fact for filtering the coolant around the fuel. Wear and tear in the reactor… read more

In traditional manufacturing, it is said that when choosing a process, it’s best to opt for the one that removes the largest amount of material in the quickest amount of time. This applies to additive manufacturing as much as it does subtractive manufacturing. Sure, the part may need finessing before it’s a fully net shaped part, but in most cases, getting the bulk of the basic geometry formed as fast as physically possible without ruining the piece is the way to go. This is why injection molding and casting are preferred for rapid creation of net shape parts. All the deposition happens more or less in one go. In order for AM to even begin to compete with these methods, it needs to increase the deposition rate of the material. The Saint Exupéry Institute for Research in Technology (IRT), France, has raised the bar in that regard and has set… read more

Researchers from the United Arab Emirates University are exploring the development of recycled composite materials using leftover 3D printed PLA and carbon fiber waste. Plastic consumption has been on the rise since its invention over a century ago, resulting in polluting waste that poses a challenge for both humanity and the rest of Earth’s ecosystem. In recent years especially, there’s been a push towards ‘green initiatives’ that work to realize a more sustainable society. One such initiative is recycling, whereby polymers like 3D printed PLA waste are repurposed for new applications. Similarly, composite materials have also seen increased demand over the years, with carbon fiber reinforcements having applications in both conventional manufacturing and 3D printing. Much like polymers, the widespread use of carbon fibers in industries such as automotive and aerospace is fueling an ever-worsening waste issue. Taking the opportunity to strike two birds with one stone, the UAE researchers… read more

It’s been a good few weeks for 3D printed rocket stories. But those have been designed for space launches. This time, we will be looking at rockets designed for ground use. Specifically, a YouTube channel (Ordnance Lab) has released a video this week demonstrating their home made rocket launcher. In fact, not just one but TWO rocket launchers with printed rockets to boot. They claim it is the world’s first printed rocket. We have seen printed rocket caps before, but it seems this may be the first fully printed rocket body. 75mm rocket launcher. (Image credit: Ordnance Lab) Rocket A rocket in its simplest form is basically a tube with a bunch of fire coming out the back, utilizing Newton’s 3rd law of motion to hurtle itself towards a target, be it outer space, or something on Earth that needs destroying. A rocket launcher is an even simpler tube, used… read more