The shipbuilding process, like aerospace development, often requires the construction of scale models of the vehicle in question in order to validate certain aspects of the design before splashing out on a full scale manufactured product. You have seen this with aircraft in wind tunnels, where the geometric model is used to represent the aerodynamic surfaces on an aircraft in flight. Similarly, ship models of various scales are used for a variety of fluid dynamic analyses in various fluid testing facilities. With ships, the models can take around 3 weeks to build out of wood, which is typically carved up via CNC. South Korean shipbuilder Daewoo Shipbuilding & Marine Engineering Co. has teamed up with Ingersoll to utilize thermoplastic additive manufacturing to produce these models, resulting in a 40 percent reduction in build time. You see the 10-meter long ABS model being printed in the image below. ABS ship scale… read more

Our Blog

Researchers at the University of Bath have developed a way to make PLA material break down using just UV light. Polylactic acid, or PLA, has long touted its ‘biodegradable’ label as a badge of honor, but the truth is that PLA is only compostable under very strict industrial conditions. Simply by adding some sugar into its composition, scientists at the university’s Centre for Sustainable and Circular Technologies (CSCT) have now shown that the 3D printing industry’s most widely-used polymer can indeed degrade in natural conditions. The University of Bath was where Dr. Adrian Bowyer invented RepRap in 2004 and kickstarted the open-source FFF movement, so there’s already a rich 3D printing legacy on campus. The team led by Dr. Antoine Buchard now carries the torch almost two decades later. Buchard said, “This strategy remains to be translated to real-life plastics objects and tested with sunlight, but we hope our technology… read more

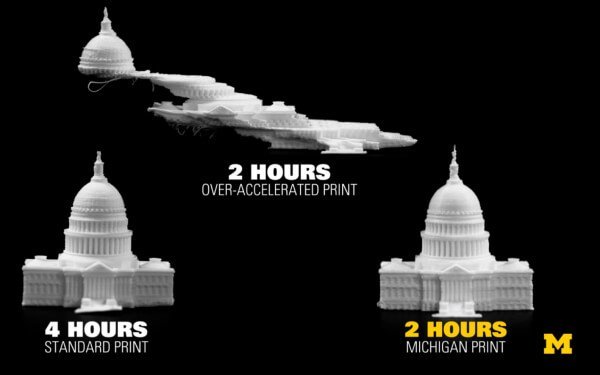

Vibrations in a 3D printer can cause all kinds of headaches with the final quality of a print. In order to reduce the amplitude of these vibrations, printing is normally done at a lower speed. And this is a severe limiting factor in the productivity of a 3D printer. What if you could crank the speed up and still get a sweet print? Researchers at University of Michigan have been asking the same question for quite a while now, and they have announced that the results of their labors have been fruitful. How fruitful? Well, as the headline says, double fruitful! Yes, by using some clever algorithms the engineers have developed a method of compensating for these vibrations via use of a software package, which has now hit the market. The software is called “FBS” which stands for “Filtered B Splines”, which describes the geometric functions that the software uses… read more

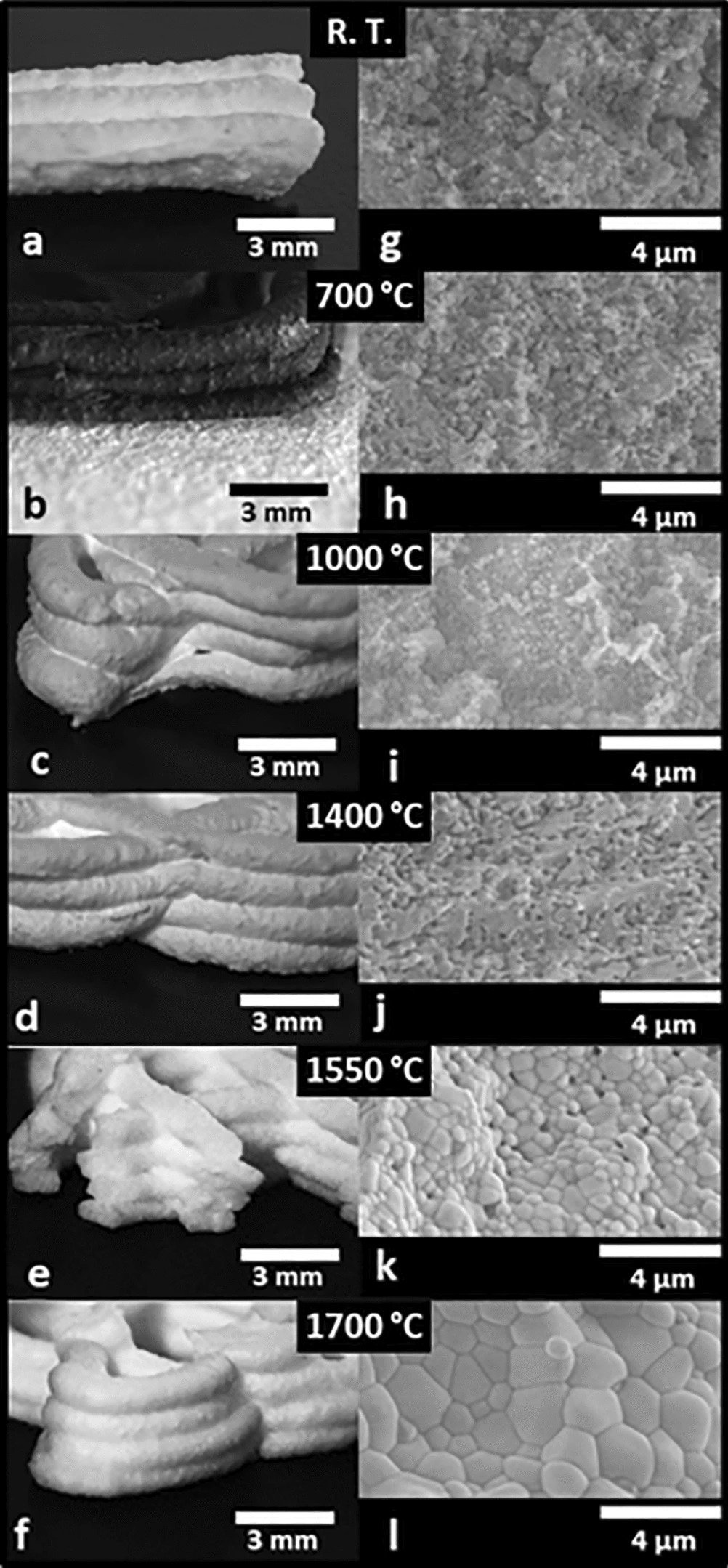

New research carried out by the French Space Agency (CNES) is investigating how 3D printed oxide ceramic materials could improve the design of crucial subsystems for space propulsion. The research focuses on the development of an optimized yttrium aluminum garnet (YAG) xerogel that offers desirable strength and creep-resistant properties when 3D printed into complex shapes. According to CNES, these additively manufactured YAG ceramics could form the basis of metal alloys used in future turbine blades for deep space exploration. The 3D printed YAG ceramic structures. Image via Scientific Reports. Ceramic 3D printing for space 3D printed ceramics are being increasingly explored for a range of space-related applications, due to the materials’ desirable mechanical properties and the geometric design possibilities enabled by additive manufacturing technologies. For some years now, 3D printed ceramics have been leveraged for the creation of enhanced components within next-generation rocket engines, alongside other novel aerospace applications. One… read more

We have looked at volumetric printing before on this website. You may recall that volumetric printing differs from traditional 3D printing as volumetric printing is non-planar; it has no flat layers. With volumetric printing, instead of a layerwise deposition, the laser light is shone into a vat of rotating transparent photopolymer resin, curing the resin into a part as the targeted laser hits the rotating medium. The resin is cured in three dimensions simultaneously, rather than in two dimensions like a normal resin printer. Typically, a resin needs to be transparent for the laser to pass through, but this may be about to change thanks to a team of researchers at École polytechnique fédérale de Lausanne (EPFL) in Switzerland, who have figured out how to print through opaque resins. You can see this demonstrated in the tiny printed Yoda figure below. “Judge me by my size do you, hm?” (Image… read more