America’s most prominent 3D printing event, RAPID + TCT, kicked off this week in Detroit with more than 400 exhibitors showcasing their product and service offerings on the trade show floor. 3D Printing Industry is reporting live from the event all week, and you can take a first glance at all the RAPID + TCT 2022 news here. This round-up looks at new materials launched during the event so far, featuring updates from Formlabs, Uniformity Labs, Jabil, Trumpf, Morf3D, 6K Additive, and more. A selection of parts 3D printed with Formlabs’ PU Rigid 650 Resin. Photo via Formlabs. Formlabs announces new PU resins Kickstarting the material launches at RAPID + TCT 2022 is resin-based 3D printer manufacturer Formlabs, which has added two new polyurethane (PU) resins to its engineering resin portfolio. Designed for the production of rigid and durable parts, PU Rigid 650 Resin and PU Rigid 1000 Resin are… read more

Our Blog

May 21, 2022 Leave a Comment Researchers at University of Chicago have found a novel way to physically model Earthquakes which have been shown to have a fairly high similarity with computer simulations of Earthquakes. The team realised that during Earthquakes occurring in basin areas, such as that which struck Mexico City in 1985, exhibit more damage around the edge of the basin. Until now, it has been difficult to determine why this may be. But thanks to 3D printing and lasers, the researchers have been able to gain some insight into this phenomenon. Beneath the ground, the earth forms into layers over time. These layers have different material properties. Some are soft like clay, and others are brittle like shale. The interactions between these layers during an earthquake are not so easy to understand. “Simulating all of this is really hard to do, not only because it’s computationally intensive,… read more

Researchers from four of Israel’s leading universities have developed a novel 3D printing process that could help to preserve vital coral reefs across the globe. Combining 3D scanning, environmental DNA sampling, and 3D printing algorithms, the team successfully produce a unique 3D printed ceramic reef capable of sustaining life and encouraging the regrowth of entire reef ecosystems. “The rapid decline of coral reefs has increased the need for exploring interdisciplinary methods for reef restoration,” said Natalie Levy, a PhD student at Bar-Ilan University. “Examining how to conserve the biodiversity of coral reefs is a key issue, but there is also an urgent need to invest in technology that can improve the coral ecosystem and our understanding of the reef environment.” 3D printing the coral reef. Photo via Ofer Berman. Replacing lost coral reefs with 3D printing Due to factors such as global warming and accelerated urbanization in coastal areas, the… read more

May 18, 2022 Leave a Comment Wisconsin-based company PrintFoam wants you to stop designing plastic lattices with your fancy generative design and topology optimization software and start designing for foams instead. Afterall, many of the lattices designed in these softwares are just trying to mimic the behavior of foams anyway, with their light densities and whatnot. So why not cut out the middleman and just churn out printed foams? Why not indeed. Because PrintFoam wants you to know that with their newly launched resin-based printed foam system, they can churn out plywood sized sheets of foam in mere minutes, rather than hours. And it’s not just sheets. It’s 3D printing so you can obviously do more complex geometries.Check out the printed foam drone nose in the image below, designed to replace a traditional styrofoam version. Styrofoam vs printed foam. (Image credit: PrintFoam) The system works by …uhhh…. Actually, there isn’t… read more

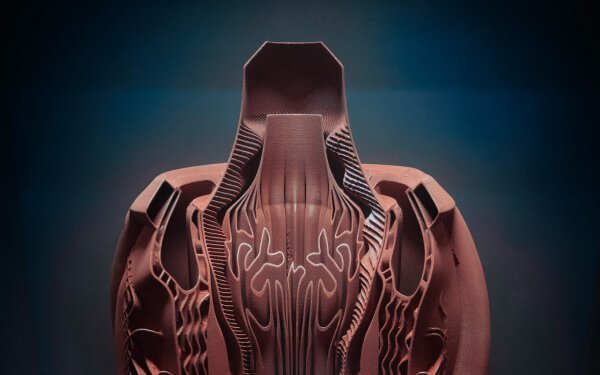

May 13, 2022 Leave a Comment Traditional rockets are incredibly inefficient for a number of reasons, not least due to the fact that they are mostly disposable. But reusability aside, another reason that rockets are inefficient is the fixed geometry of the bell nozzle. Efficient rocket thrust is dependent on the exhaust gas going in the correct direction (opposite to direction of travel, ideally). A bell shaped rocket nozzle (also called a convergent/divergent, or “con-di” nozzle) shapes the exhaust gasses so they flow out in more or less a straight vector. But as it exits the nozzle, the flow encounters the atmosphere, which also shapes the flow. Aerospike engine (Image credit: Hyperganic) At low altitudes, the ambient pressure is enough to tame the flow into a straight path. However, once the altitude increases and the ambient pressure decreases, the pressure affects the flow less and hence the exhaust “expands” as… read more