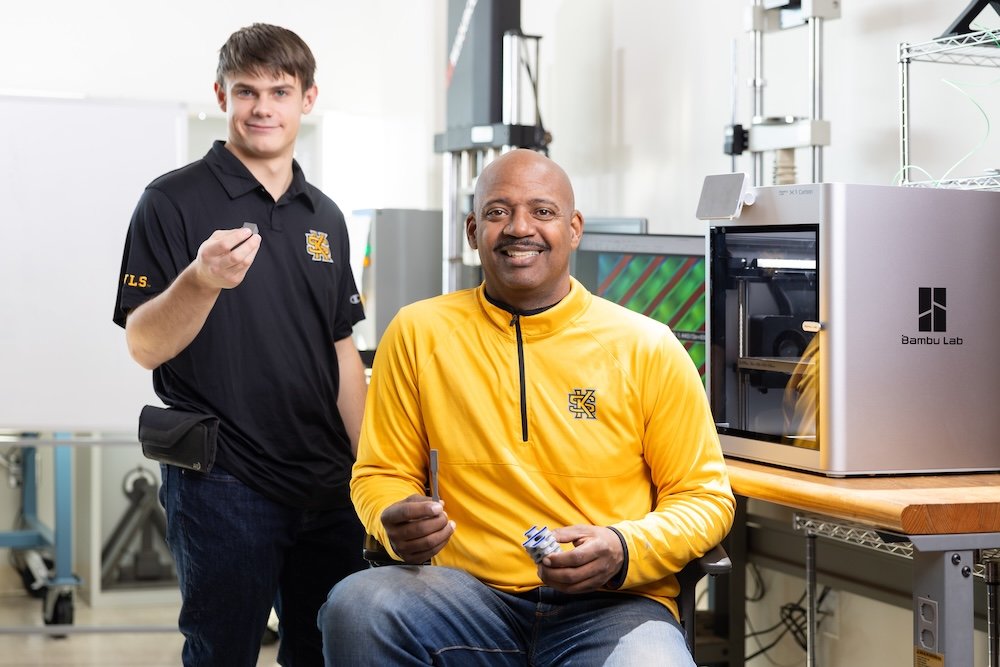

Researchers at Kennesaw State University in the United States have found that adjusting 3D printing settings can nearly triple the strength of printed parts, paving the way for safer, more efficient designs in high-stakes applications like nuclear energy. The project, supported by the Summer Undergraduate Research Program and the Sophomore Scholars Program, is led by Aaron Adams, assistant chair of the Department of Engineering Technology, and carried out by mechatronics engineering student Eric Miller at KSU’s START Lab. The team explores how subtle changes in lattice angles, densities, and internal channels influence material behavior. Adams notes that these improvements could help address inefficiencies in nuclear fuel systems, where tightly packed fuel pellets have little room to expand. “Right now, the fuel is in the form of a pellet about the size of a penny, and the pellets are stacked together like a roll of coins,” said Adams, an associate professor… read more

3D Printing Research

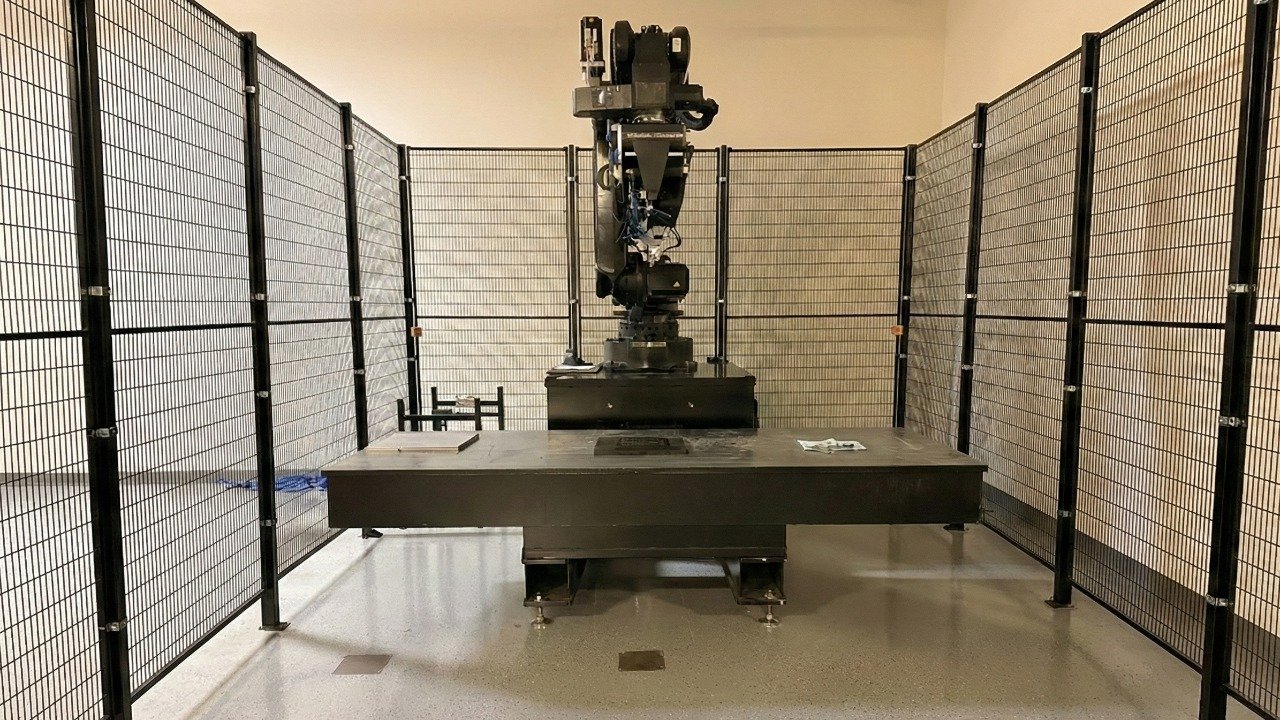

Auburn University, a public land-grant research university, has strengthened its advanced manufacturing portfolio with the addition of a CF3D Enterprise system from Continuous Composites, now installed at the Auburn University Research and Innovation Campus. The new capability reinforces the Huntsville site’s position within a rapidly expanding regional hub for hypersonic research and development. This investment reflects Auburn’s continued focus on next-generation composite manufacturing. Paired with the CF3D Studio software, the system enables the production of high-performance continuous-fiber composite structures, supporting research efforts that address some of the most demanding challenges in aerospace and defense applications. The CF3D Enterprise Cell. Photo via Auburn University. A Strategic Location for Hypersonics Research The Huntsville campus is embedded within a dense network of defense contractors, aerospace companies, and organizations leading key programs. The site hosts the Auburn University Applied Research Institute and offers adaptable laboratories, modeling and simulation tools, secure research spaces, and dedicated… read more

Researchers from the University of Washington (UW) have introduced a new way to 3D print mycelium-based biocomposites, sidestepping the need for traditional molds. Led by Danli Luo, alongside Junchao Yang, and Nadya Peek this approach uses a specialized 3D printable paste called Mycofluid, a custom-built 3D printing system named Fungibot, and an incubation process that allows mycelium to grow within printed structures. Published in the 3D Printing and Additive Manufacturing journal, the study highlights how this method could offer a more sustainable alternative to conventional fabrication without compromising on functionality. Mycelium biocomposites offer structural strength and hydrophobic properties, but rigid molds limit design flexibility. Attempts with flexible formworks like knitting or weaving have led to uneven material distribution and structural inconsistencies, says the team. “We’re interested in expanding this to other bio-derived materials, such as other forms of food waste,” Luo said. “We want to broadly support this kind of… read more

Researchers from John Hopkins University have developed a new 3D printing programming language called Time Code (T-Code). Outlined in a Nature Communications study, co-authors Sarah Propst and Jochen Mueller claim T-Code improves 3D printing speed and quality for complex multi-material parts. Optimized for Direct Ink Writing (DIW) additive manufacturing, this new approach uses a Python script to divide traditional G-Code into two separate tracks. One controls the 3D print path, while the other manages printhead functions. Unlike G-Code, which executes tasks line-by-line, T-Code uses time to synchronize the 3D printer’s motion with key commands like material switching and flow adjustments. This eliminates common start-stop interruptions that slow production and create defects, enabling continuous, uninterrupted fabrication. As a result, 3D printing becomes faster without losing accuracy or detail, facilitating advanced capabilities like smooth gradients and in-situ material changes. According to the Baltimore-based researchers, their new methodology can handle complex designs that… read more

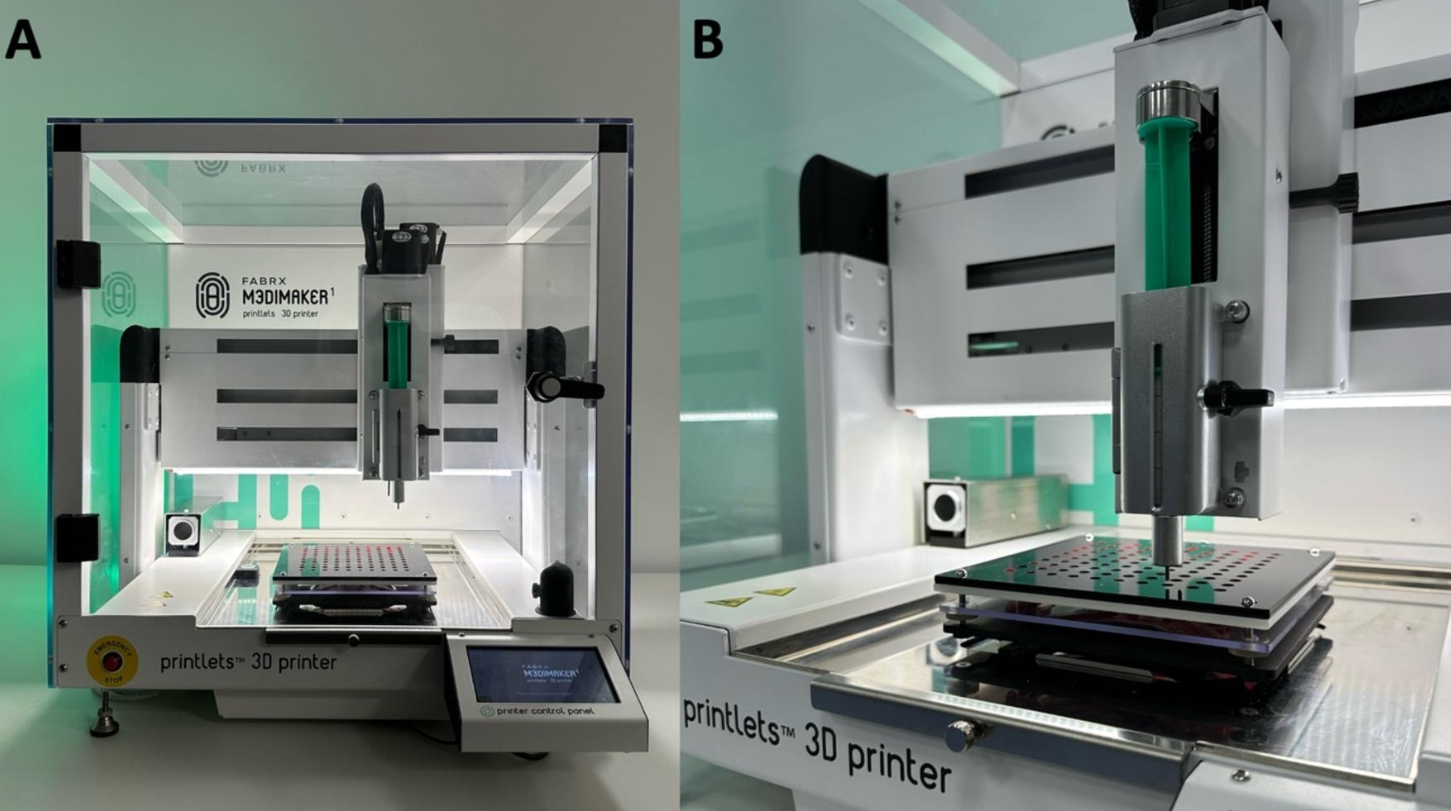

UK-based biotech company FabRx has announced a study exploring how pharmaceutical 3D printing can automate capsule filling in community pharmacies. Published in the International Journal of Pharmaceutics, the research examines the effectiveness of the M3DIMAKER 1 pharmaceutical 3D printer in producing minoxidil capsules, evaluating its cost, time efficiency, and safety compared to traditional manual methods. According to the team, pharmacists often rely on manual compounding, a process that demands time and carries the risk of human error. By using semi-solid extrusion (SSE) technology, the biotech company’s 3D printer simplifies capsule filling, ensuring precise dosing and better consistency. M3DIMAKER 1 pharmaceutical 3D printer with the capsule holder on top of the integrated balance: (A) Full view of the capsule holder- pharmaceutical 3D printer system in a community compounding pharmacy laboratory, (B) Magnified view of the capsule holder within the printer. Image via FabRx. Advanced capsule production with 3D printing One of… read more