ASTM International, a global standards organization, has been awarded $2.1 million by America Makes to advance sustainability in 3D printing. “We are pleased to lead this important project with America Makes,” said Mohsen Seifi, ASTM’s Vice President of Global Advanced Manufacturing. “Our focus will be on developing methodologies that eventually promote the sustainable use of materials in additive manufacturing, ensuring both environmental benefits and high-quality outcomes for end users.” The consortium includes Boeing, ADDMAN, Amaero Advanced Materials and Manufacturing, and the Additive Manufacturer Green Trade Association (AMGTA). “Advancing sustainable practices in additive manufacturing is crucial for the future of aerospace and other industries,” said Melissa Orme, Vice President of Additive Manufacturing at Boeing. “This project represents a major step toward achieving those goals by addressing full lifecycle assessment and sustainable design considerations” Reuse and recycling of Additive Manufacturing materials The project will focus on developing methodologies for reutilizing and recycling… read more

3D Printing Research

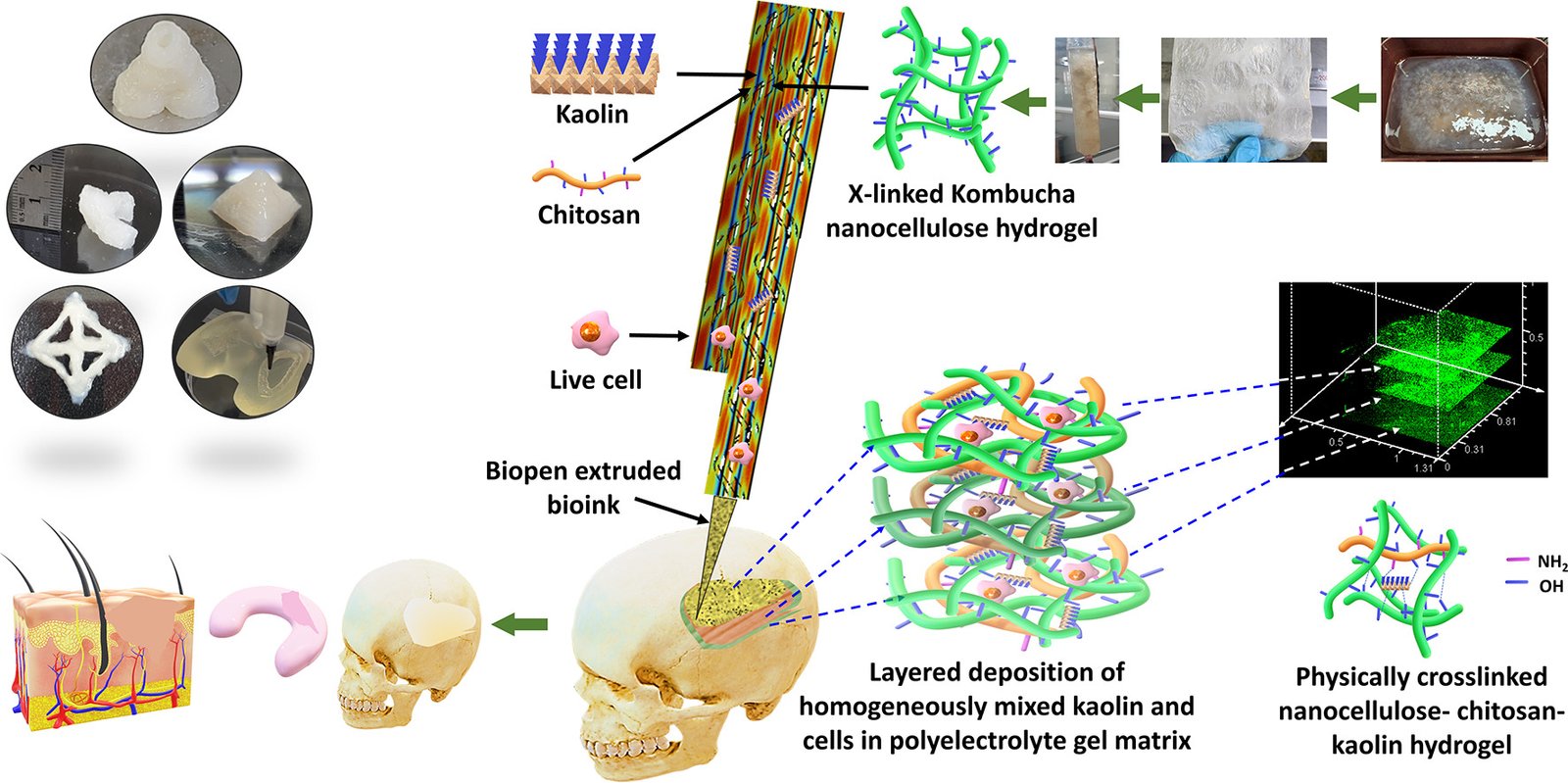

Researchers at Seoul National University of Science and Technology (SEOULTECH) have developed a Kombucha SCOBY (Symbiotic Culture of Bacteria and Yeast) bioink that could streamline in vivo tissue engineering. Published in the International Journal of Biological Macromolecules on December 1, 2024, the study outlines how nanocellulose from SCOBY can be partially hydrolyzed, reinforced with chitosan and kaolin, and printed onto irregular wounds using a hand-held device called the Biowork biopen. Kombucha SCOBY produces cellulose during tea fermentation, resulting in nanocellulose with biodegradable and cell-compatible properties. However, the default entangled structure can be difficult to extrude. The team, led by Professor Insup Noh, used acetic acid to loosen the nanocellulose fibers (partial hydrolysis), improving flow through fine nozzles but simultaneously reducing the material’s mechanical strength. To restore structural stability, they introduced chitosan (a positively charged polymer) and kaolin (a negatively charged clay). Electrostatic interactions among these three components—nanocellulose, chitosan, and kaolin—created… read more

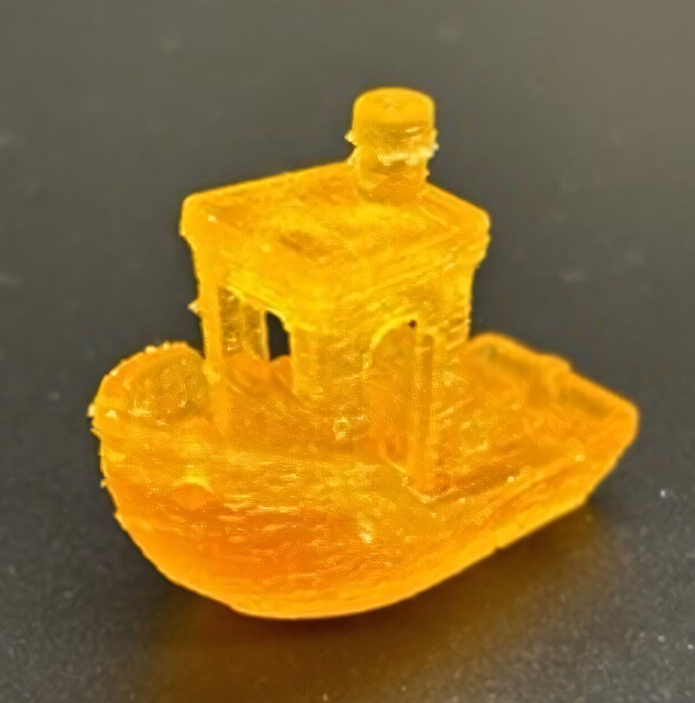

Researchers at Duke University have developed a solvent-free polymer for digital light processing (DLP) 3D printing, aimed at enhancing mechanical properties and environmental compatibility, particularly for medical applications. Published in Angewandte Chemie International Edition, this development marks one of the first solvent-free resins suitable for Digital Light Processing (DLP) 3D printing, eliminating the need for solvent-based dilution in the printing process, according to the researchers. DLP technology uses light to solidify liquid resin into layered structures, commonly used in industrial and dental fields. However, many polymers suited for DLP printing require a low-viscosity resin, similar to water, to achieve high resolution. To reduce viscosity, traditional methods often use solvents, which can introduce challenges such as up to 30% shrinkage in printed parts and residual stress from solvent evaporation, negatively impacting dimensional accuracy and mechanical strength. “I wanted to create an inherently thin, low-viscosity material for DLP to use for degradable… read more

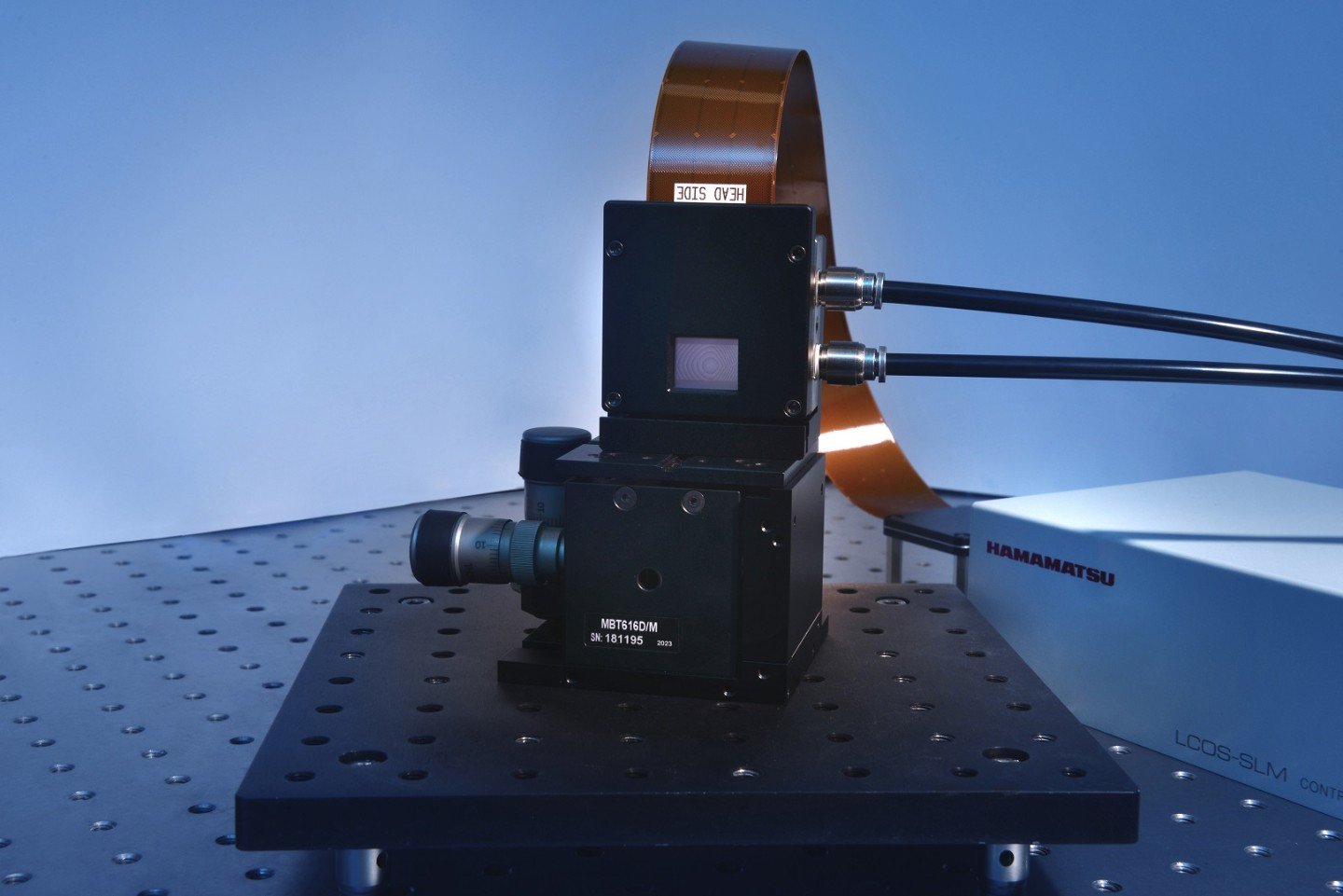

German research organization Fraunhofer Institute for Laser Technology ILT will showcase its new 3D printing beam shaping technology at Formnext 2024. Working with the Chair of Technology of Optical Systems (TOS) at RWTH Aachen University, the new platform, the Fraunhofer team is developing a test system for investigating complex laser beam profiles. This platform can create customized beam profiles for laser powder bed fusion (LPBF) 3D printing, enhancing part quality, process stability and productivity, while minimizing material waste. Fraunhofer ILT’s new system uses Liquid Crystal on Silicon – Spatial Light Modulators (LCoS-SLMs) to selectively bend the phase front of the laser beam during 3D printing. It can reportedly achieve more complex profiles than the basic ring and rectangular shapes achieved in previous research. This will allow researchers to investigate almost any beam profile used in LPBF. The complex profiles can then be matched with specific industrial 3D printing applications to… read more

A recent advance in bioprinting from the Collins BioMicrosystems Laboratory at the University of Melbourne could significantly reshape tissue engineering. Researchers at the lab, led by biomedical engineer David Collins, have introduced a new 3D bioprinting approach called Dynamic Interface Printing (DIP). Unlike traditional methods that slowly build tissue layer by layer, DIP employs acoustic waves to guide cells into precise configurations, producing complex human tissues in seconds—a process previously hindered by speed and structural limitations. This breakthrough offers the potential for customized, high-fidelity tissue structures with applications across regenerative medicine and disease modeling. The approach can reportedly achieve 3D printing speeds around 350 times faster than those of traditional bioprinters, reducing the chances of cell damage while maintaining high structural accuracy. Most current bioprinters rely on layer-by-layer construction, which often compromises cell viability due to prolonged exposure times and complex post-processing steps. Once printed, tissue structures typically require delicate… read more