The Additive Manufacturer Green Trade Association (AMGTA) has issued a report outlining a new method of passivating metal powder condensate waste from the 3D printing process. Developed by Sintavia, a service bureau for aerospace parts, and powder specialist KBM Advanced Materials, the new process involves adding the powder waste to a resin material to create a non-hazardous mixture. This allows the waste to be safely transported to recycling plants, where it can be reclaimed from the resin matrix and reused in additive manufacturing. According to Sherri Monroe, the AMGTA’s Executive Director, the latest report is a “must-read” for companies that operate with laser powder bed fusion (PBF) technologies. She adds, “Not only does this new process reduce transportation costs, but it is also reversible, meaning that metal recycling companies can have unsoiled access to the underlying powder once it is received—thus allowing for the potential to recycle waste material that… read more

3D Printing Research

A group of Italian researchers has developed a 3D printed artificial skin that could be used to improve the tactile sensing capabilities of robots. Researchers from Scuola Superiore Sant’Anna, Ca’ Foscari University of Venice, and the Sapienza University of Rome created the 3D printed skin which successfully mimicked the function of Ruffini receptors, a type of cell located on subcutaneous human skin tissue that detect stretching, vibrations, warmth, and pressure. Once attached to a robot and combined with a deep learning algorithm based on a multi-layered convolutional neural network (CNN), the skin can estimate the force and point at which the robot comes into contact with an object, potentially enabling safer human-robot cooperation in the future. The 3D printed artificial skin. Image via Nature Machine Intelligence. 3D printing artificial skin 3D bioprinted skin models and grafts have received increasing interest and development in recent years due to their potential uses… read more

Researchers from the Khalifa University of Science and Technology in Abu Dhabi are investigating the 3D printing of multifunctional optical fibers. Using polymer-based stereolithography (SLA) technology, the team 3D printed a set of optical fiber designs and integrated thermochromic micro-powder pigments, making them responsive to changes in temperature. At the same time, owing to the optical properties of the fibers, the researchers also managed to endow their designs with strain sensing capabilities. By exhibiting sensitivity to two stimuli simultaneously, the 2-in-1 optical fibers show great promise in biomedical and healthcare applications for remote temperature and strain sensing devices. The research paper writes, “This work may pave the way towards developing tunable thermochromic sensors that are cost-effective, reusable, and flexible.” The Khalifa University campus. Photo via Khalifa University of Science and Technology. Additive manufacturing for sensing applications The list of temperature sensor use cases is a long one, including medical diagnostic… read more

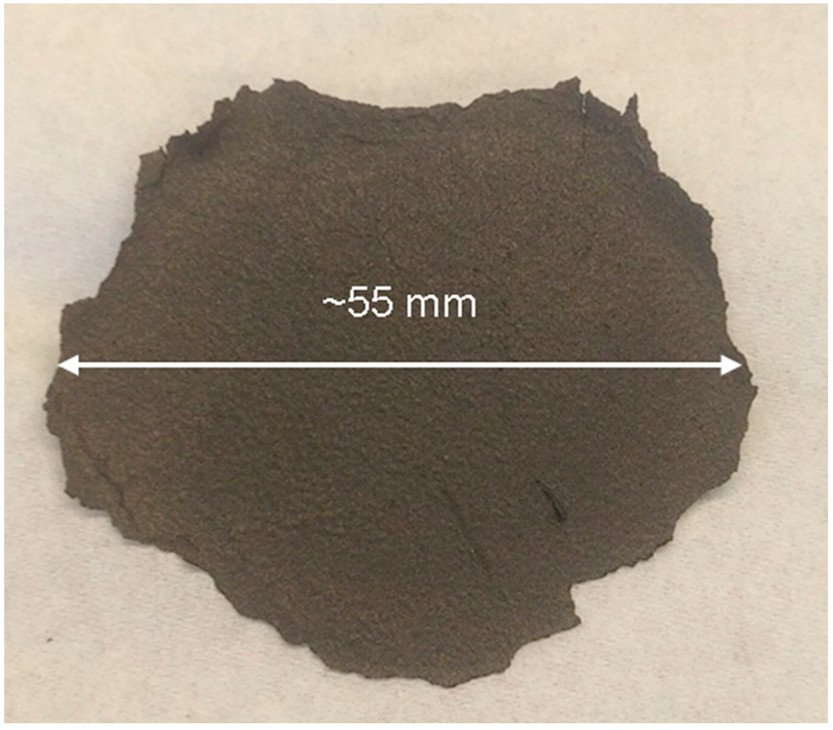

Researchers from Concordia University, Montreal, are exploring the 3D printing of graphene oxide liquid crystals to enable materials with previously-unseen levels of strength. Having made headlines for over a decade, graphene is one of those wonder materials that promised to solve a number of our engineering challenges. The sheet-form carbon allotrope comprises a single layer of atoms arranged in a 2D nanostructure resembling a honeycomb lattice. The material is known for its high strength-to-weight ratio, excellent thermal and electrical conductivity, corrosion resistance, and scratch-resistant qualities. Unfortunately, we haven’t yet been able to translate graphene’s strength from the microscale to real-world applications in the macroscale. The Concordia team is now using photocuring, the technology behind stereolithography 3D printing, to produce self-assembled graphene oxide structures that are both larger and more complex than today’s possibilities. A large graphene oxide sheet produced via photocuring, the process behind resin 3D printing. Photo via Concordia… read more

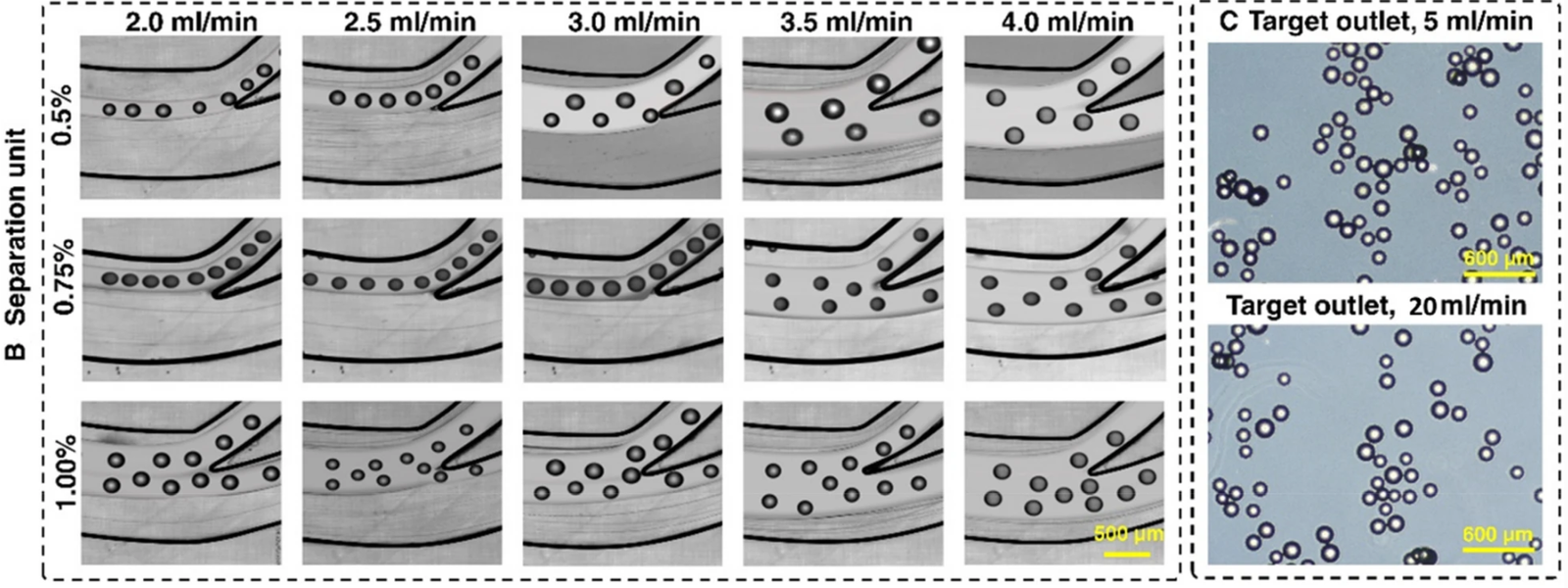

Researchers from the University of Technology Sydney (UTS), together with biotech firm Regeneus, have created what they claim is the world’s first 3D printed microfluidic device capable of harvesting stem cells. Bleeding-edge stem cell therapies are a promising way to treat a whole plethora of ailments, including arthritis, diabetes, and potentially even cancer. Stem cells work by differentiating into specialized cells, meaning they can be used to replace damaged cells around the human body. Unfortunately, harvesting and processing stem cells from donors is currently very time, cost, and labor intensive due to limitations in biotechnology. The 3D printed microfluidic device is designed to harvest stem cells from bioreactors, offering a scalable method of processing stem cells without the associated costs. Professor Majid Warkiani, the UTS biomedical engineer leading the research, said, “Our cutting-edge technology, which uses 3D printing and microfluidics to integrate a number of production steps into one device… read more