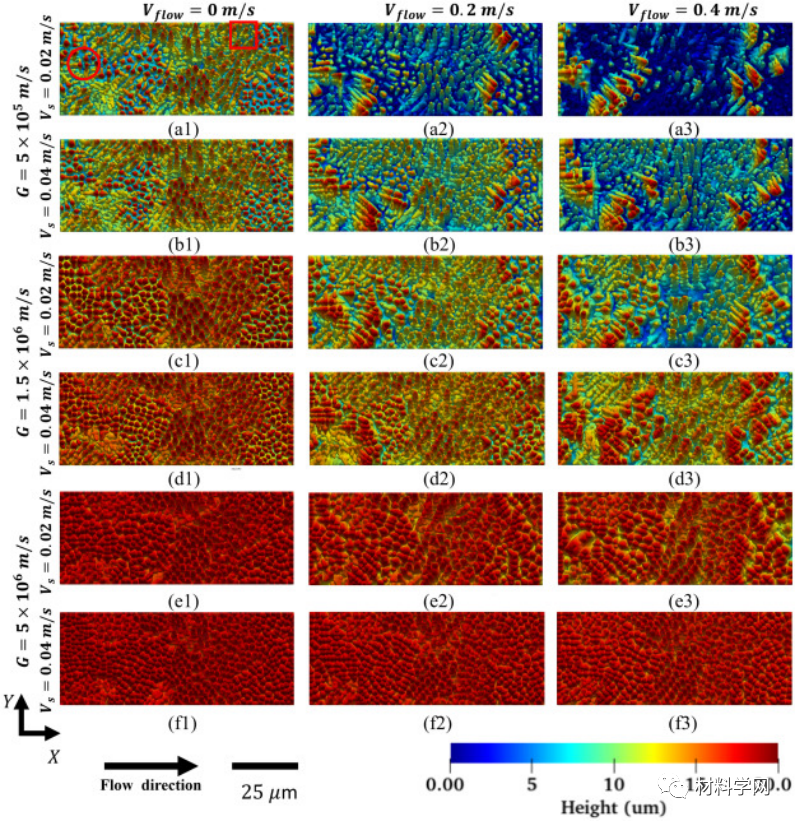

Researchers from Tsinghua University and the National University of Singapore are investigating the effects of fluid flow on the mechanical properties of metal 3D printed parts. When it comes to metal additive manufacturing technologies like laser powder bed fusion, carefully controlling the formation of new grains and dendrites in printed parts is crucial for tuning the final grain structure. This is important because grain structure and grain size have a significant effect on almost all mechanical properties, including hardness, yield strength, tensile strength, fatigue strength, and impact strength. There are a whole host of factors and parameters that can influence the formation of new grains and dendrites in 3D printing, but temperature gradient and solidification velocity are already thought to be prime determinants. According to the researchers however, the effects of fluid flow in the melt pool of a 3D printed part haven’t yet been investigated. SEM imaging of a… read more

3D Printing Research

Researchers at the University of Bath have developed a way to make PLA material break down using just UV light. Polylactic acid, or PLA, has long touted its ‘biodegradable’ label as a badge of honor, but the truth is that PLA is only compostable under very strict industrial conditions. Simply by adding some sugar into its composition, scientists at the university’s Centre for Sustainable and Circular Technologies (CSCT) have now shown that the 3D printing industry’s most widely-used polymer can indeed degrade in natural conditions. The University of Bath was where Dr. Adrian Bowyer invented RepRap in 2004 and kickstarted the open-source FFF movement, so there’s already a rich 3D printing legacy on campus. The team led by Dr. Antoine Buchard now carries the torch almost two decades later. Buchard said, “This strategy remains to be translated to real-life plastics objects and tested with sunlight, but we hope our technology… read more

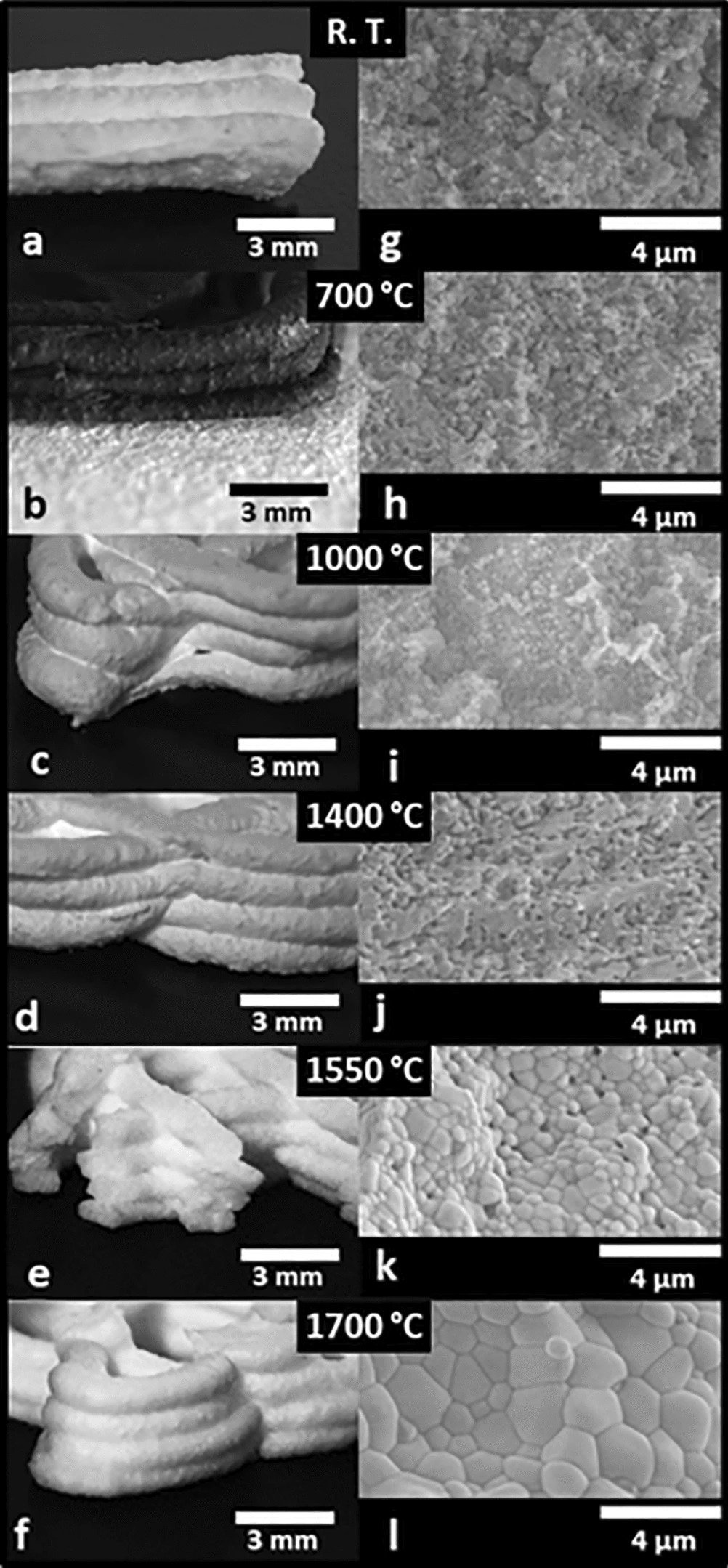

New research carried out by the French Space Agency (CNES) is investigating how 3D printed oxide ceramic materials could improve the design of crucial subsystems for space propulsion. The research focuses on the development of an optimized yttrium aluminum garnet (YAG) xerogel that offers desirable strength and creep-resistant properties when 3D printed into complex shapes. According to CNES, these additively manufactured YAG ceramics could form the basis of metal alloys used in future turbine blades for deep space exploration. The 3D printed YAG ceramic structures. Image via Scientific Reports. Ceramic 3D printing for space 3D printed ceramics are being increasingly explored for a range of space-related applications, due to the materials’ desirable mechanical properties and the geometric design possibilities enabled by additive manufacturing technologies. For some years now, 3D printed ceramics have been leveraged for the creation of enhanced components within next-generation rocket engines, alongside other novel aerospace applications. One… read more

Researchers from four of Israel’s leading universities have developed a novel 3D printing process that could help to preserve vital coral reefs across the globe. Combining 3D scanning, environmental DNA sampling, and 3D printing algorithms, the team successfully produce a unique 3D printed ceramic reef capable of sustaining life and encouraging the regrowth of entire reef ecosystems. “The rapid decline of coral reefs has increased the need for exploring interdisciplinary methods for reef restoration,” said Natalie Levy, a PhD student at Bar-Ilan University. “Examining how to conserve the biodiversity of coral reefs is a key issue, but there is also an urgent need to invest in technology that can improve the coral ecosystem and our understanding of the reef environment.” 3D printing the coral reef. Photo via Ofer Berman. Replacing lost coral reefs with 3D printing Due to factors such as global warming and accelerated urbanization in coastal areas, the… read more

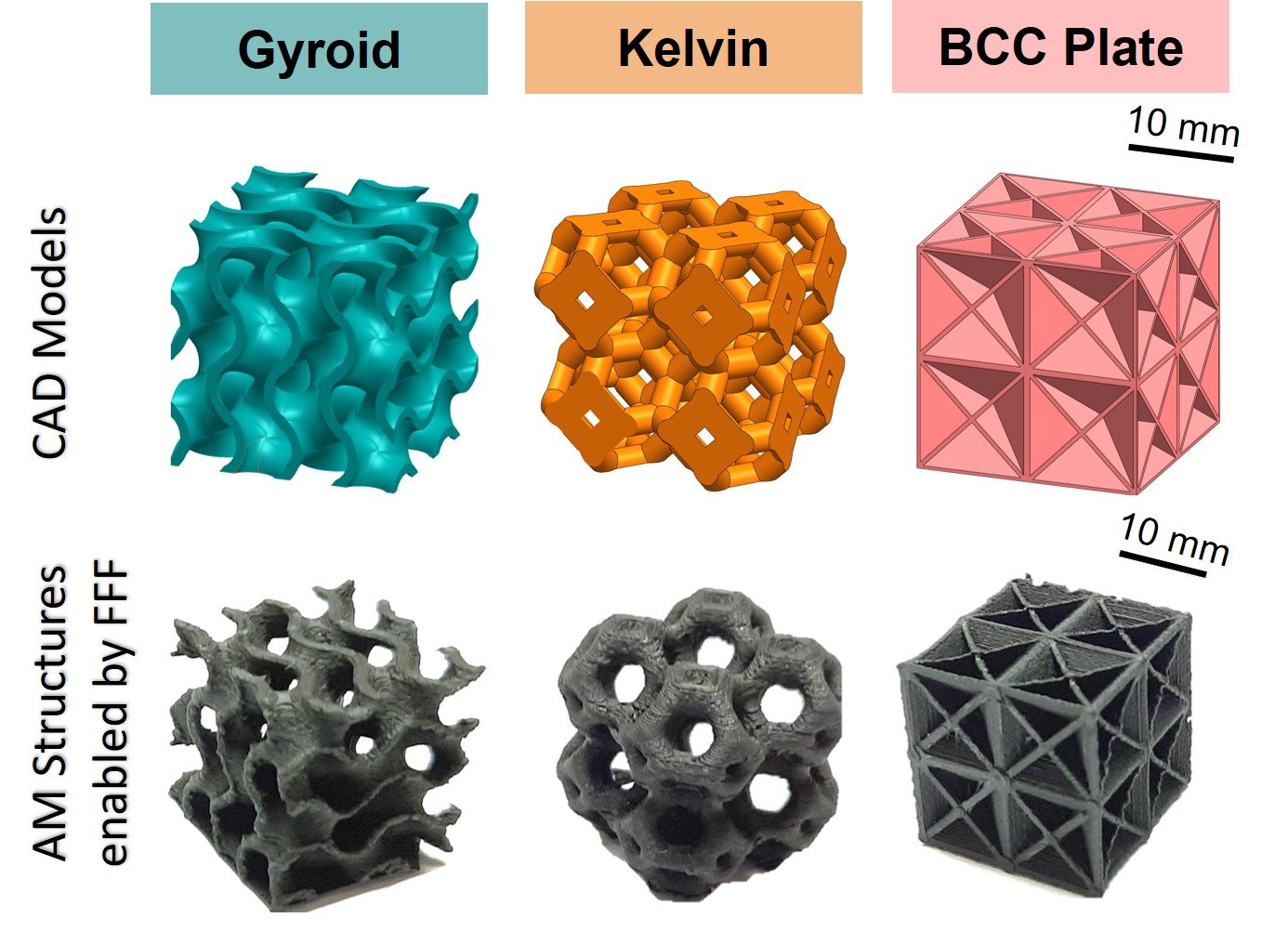

A research team led by the University of Glasgow has developed a 3D printable carbon nanotube-based plastic material capable of sensing its own structural health. Inspired by porous cellular forms like beehives, sponges, and bone found in the natural world, the novel material is reportedly tougher, stronger, and smarter than comparable conventional materials, and could find new applications in medicine, prosthetics, automotive and aerospace design, where low-density, tough materials with self-sensing abilities are desirable. “Nature has a lot to teach engineers about how to balance properties and structure to create high performance lightweight materials,” said Dr. Shanmugam Kumar of the University of Glasgow’s James Watt School of Engineering. “We’ve taken inspiration from these forms to develop our new cellular materials, which offer unique advantages over their conventionally produced counterparts and can be finely tuned to manipulate their physical properties.” The 3D printed nanoengineered designs. Image via University of Glasgow. 3D… read more