Just recently we saw how the USS Essex took to the oceans with their own metal printer for fabricating and repairing components while out to sea. This week, it’s the turn of the US Marines who have been testing their own Factory in a Box concept that will allow accurate metrology and advanced plastic and composite manufacturing out in the field. The so-called Expeditionary Fabrication Shop is a portable solution to enable manufacturing and repairs in hard to reach locales and areas without infrastructure. The project is being trialed at a Marine base in Okinawa by the III Marine Expeditionary Force. One of the mini-factory units at Camp Kinser. (Image credit: Stars and Stripes) “The intent is to supplement the supply chain and return whatever piece of equipment it is back into the fight as fast as possible,” said Gunnery Sgt. Quincy Reynolds, who is NCO in charge of the… read more

3D Printing

A team of researchers at the National Institute for Materials Science and Osaka University Graduate School of Engineering in Japan, has successfully demonstrated the fabrication of single crystal nickel with additive manufacturing, and they are hoping it finds applications in aerospace. Single crystal metals are highly prized for applications undergoing high stresses and strains and in high temperature environments such as inside a jet engine. They also crack less during manufacturing. Typically they are manufactured with casting. Traditional turbine blades used to be polycrystalline in nature, meaning that the alloy material consists of random crystals formed as the cast blade cools. The interfaces between these random grains are called the grain boundary, and these are a point of weakness in the microstructure of the material. A solution to this problem was found by carefully guiding the crystal seed growth through geometric features inside the mold to guide the solidifying blade… read more

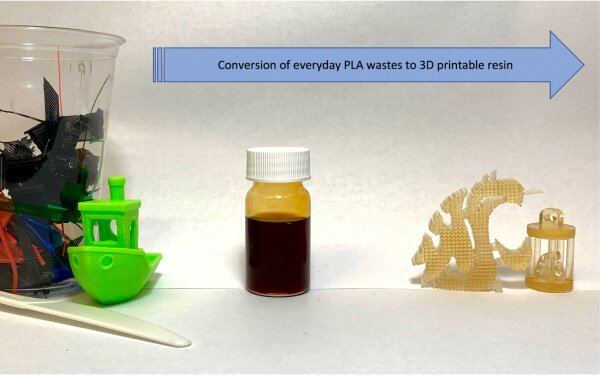

A team from Washington State University (WSU) has just received funding from the Cougar Cage to develop their process for converting waste PLA into brand new PLA resin for SLA and other photopolymer printers. Cougar Cage, for those curious, is the WSU equivalent of Shark Tank/Dragon’s Den, but for WSU staff, students and faculty. That is, it’s a contest where entrepreneurs pitch to investors to get their ideas off the ground in the style of the TV shows. One team has focused on the chemical recycling of PLA plastics, and for their efforts, they have made it through three rounds of the contest and been awarded with $50,000 of funding which will help the team develop the process to create new PLA resins from scrap. Scrap goes in > Resin comes out. (Image credit: WSU) The focus is to find alternative means of recycling PLA, because as we all know… read more

Indian aerospace engineering company Agnikul Cosmos has opened their first rocket printing factory at IIT Madras Research Park, Chennai. “Rocket Factory-1” is intended to churn out two rocket engines per week with their EOS printers and other machinery. This will allow the production of one complete launch vehicle per month. The factory contains all the tooling and hardware required to produce the whole engine in the same facility. Agnibaan rocket on Dhanush mobile launcher. (Image credit: Agnikul Cosmos) The 18m tall, 1.3m diameter, three-stage rocket is named Agnibaan, which means “arrow of fire”, and is capable of hoisting a 100 kg satellite into a 700 km orbit. According to the company website, the combustion section of the first stage will be 100% 3D printed. Looking at the image of their printed rocket motor below, it appears that this includes the injector plate, combustion chamber, cooling channels, and throat section. Printed… read more

New York-based fashion design company Simplifyber has just received 3.5 million USD in seed funding to continue development of their range of footwear and clothing. What is novel about the company is the material process they are using to create their fabrics. These fabrics are molded, not woven and stitched together, and they are molded from a mix of plant matter and other biodegradable materials. You can see the shoe in the image below. Upper molded over printed mold (Image credit: Simplifyber) First up, you will notice that the sole is clearly made with additive manufacturing, and this sole has been printed with the collaboration of HP, presumably on one of their MJF machines.But the real innovation lies in the shoe upper (the bit that covers the foot). This is the molded fabric, and it is produced with a means partly inspired by traditional paper making techniques. Like papermaking, the… read more