It’s been a good few weeks for 3D printed rocket stories. But those have been designed for space launches. This time, we will be looking at rockets designed for ground use. Specifically, a YouTube channel (Ordnance Lab) has released a video this week demonstrating their home made rocket launcher. In fact, not just one but TWO rocket launchers with printed rockets to boot. They claim it is the world’s first printed rocket. We have seen printed rocket caps before, but it seems this may be the first fully printed rocket body. 75mm rocket launcher. (Image credit: Ordnance Lab) Rocket A rocket in its simplest form is basically a tube with a bunch of fire coming out the back, utilizing Newton’s 3rd law of motion to hurtle itself towards a target, be it outer space, or something on Earth that needs destroying. A rocket launcher is an even simpler tube, used… read more

3D Printing

Colorado-based rocket engine company Ursa Major has used 3D printing to build a reusable, liquid oxygen/methane rocket engine capable of delivering 200,000 lbs of thrust. The engine, dubbed “Arroway” was partly printed in copper and other materials and will fill the gap left by the now unavailable RD-180 and RD-181 Russian engines which until recently were used on the American Atlas V rocket. Here is a fancy render of the Arroway, with an astronaut for scale. A nice render. (Image credit: Ursa Major) In a recent press release, the company, which states that they are the only privately funded company that focuses solely on rocket propulsion, announced that they were now taking orders for their Arroway engine. They have built two smaller engines on the path to Arroway. Ursa Major‘s previous engines include “Hadley,” capable of producing 5,000-pounds of thrust, and the 50,000-pound thrust “Ripley” engine. Hadley was the first… read more

The Halot-One series of resin printers from Creality offers high quality resin printing at a price friendly to most makers and 3D printing fans. At the core of the Creality Halot-One lies the Integral Light Source technology, which helps users create perfect prints. But what is the Integral Light Source and exactly how does it help keep print quality high? Read on to know more! Halot One Series The Halot One resin printer series was first released in 2021 with the original Halot-One. Since then the range has expanded to include new models including the original Halot-One, Halot-One Lite, Halot-Sky and most recently, the Halot-One Plus and Halot-One Pro. Halo there! The Halot-One Plus, and the Halot-One Pro (Image credit: Creality) The printers in the series all vary in size, but all of them have the Integral Light Source technology at their core. Most budget resin printers make use of… read more

The shipbuilding process, like aerospace development, often requires the construction of scale models of the vehicle in question in order to validate certain aspects of the design before splashing out on a full scale manufactured product. You have seen this with aircraft in wind tunnels, where the geometric model is used to represent the aerodynamic surfaces on an aircraft in flight. Similarly, ship models of various scales are used for a variety of fluid dynamic analyses in various fluid testing facilities. With ships, the models can take around 3 weeks to build out of wood, which is typically carved up via CNC. South Korean shipbuilder Daewoo Shipbuilding & Marine Engineering Co. has teamed up with Ingersoll to utilize thermoplastic additive manufacturing to produce these models, resulting in a 40 percent reduction in build time. You see the 10-meter long ABS model being printed in the image below. ABS ship scale… read more

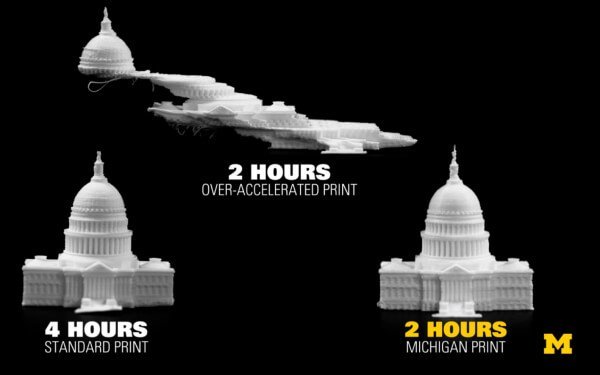

Vibrations in a 3D printer can cause all kinds of headaches with the final quality of a print. In order to reduce the amplitude of these vibrations, printing is normally done at a lower speed. And this is a severe limiting factor in the productivity of a 3D printer. What if you could crank the speed up and still get a sweet print? Researchers at University of Michigan have been asking the same question for quite a while now, and they have announced that the results of their labors have been fruitful. How fruitful? Well, as the headline says, double fruitful! Yes, by using some clever algorithms the engineers have developed a method of compensating for these vibrations via use of a software package, which has now hit the market. The software is called “FBS” which stands for “Filtered B Splines”, which describes the geometric functions that the software uses… read more