![]()

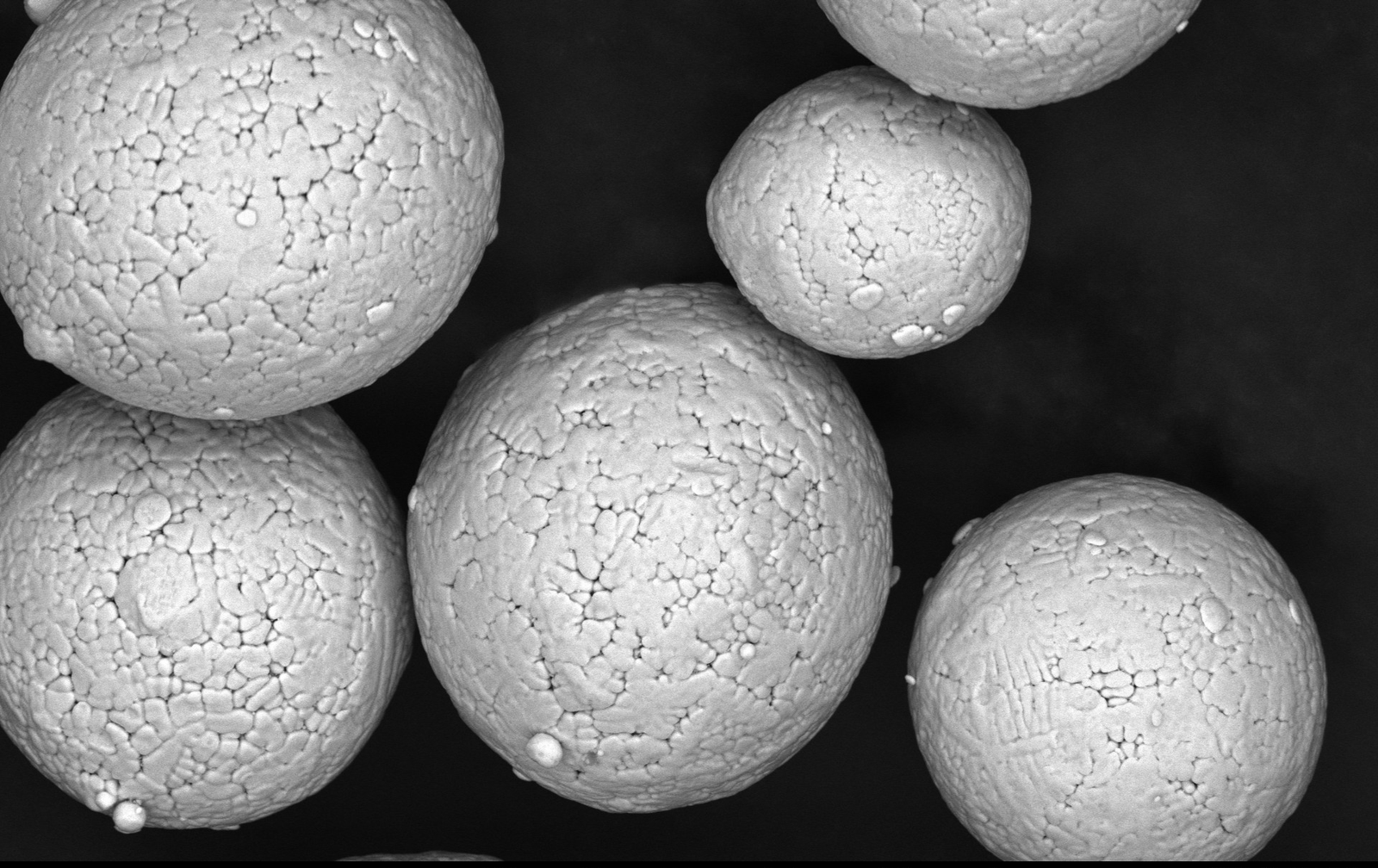

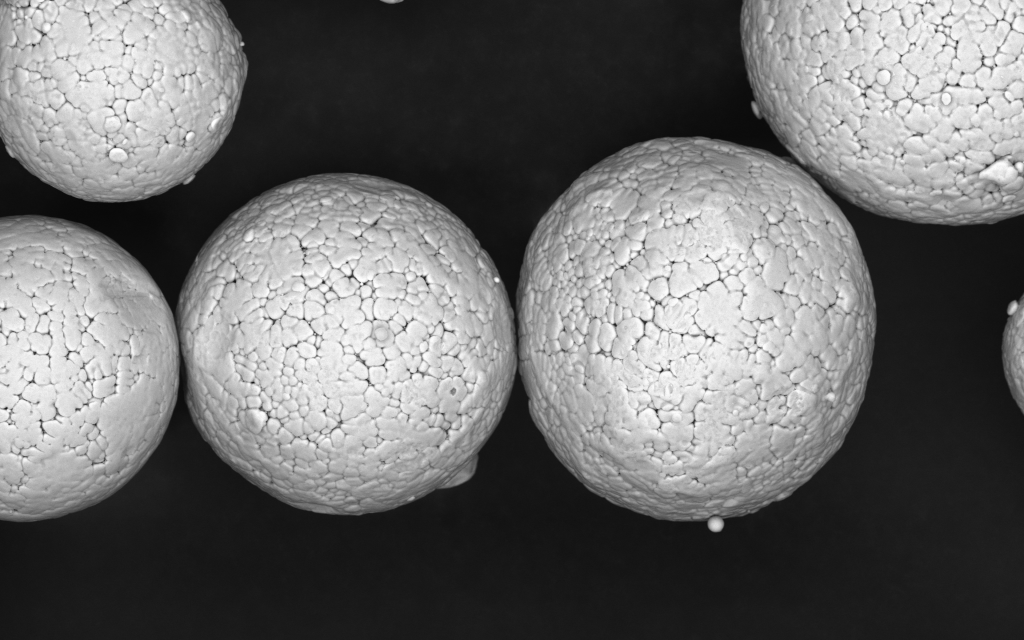

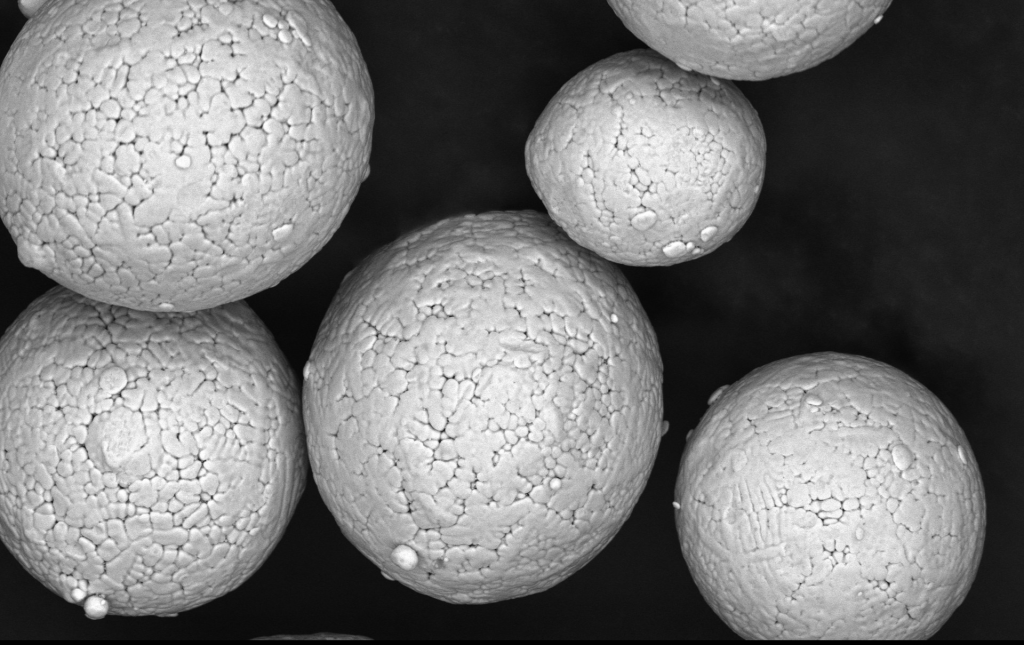

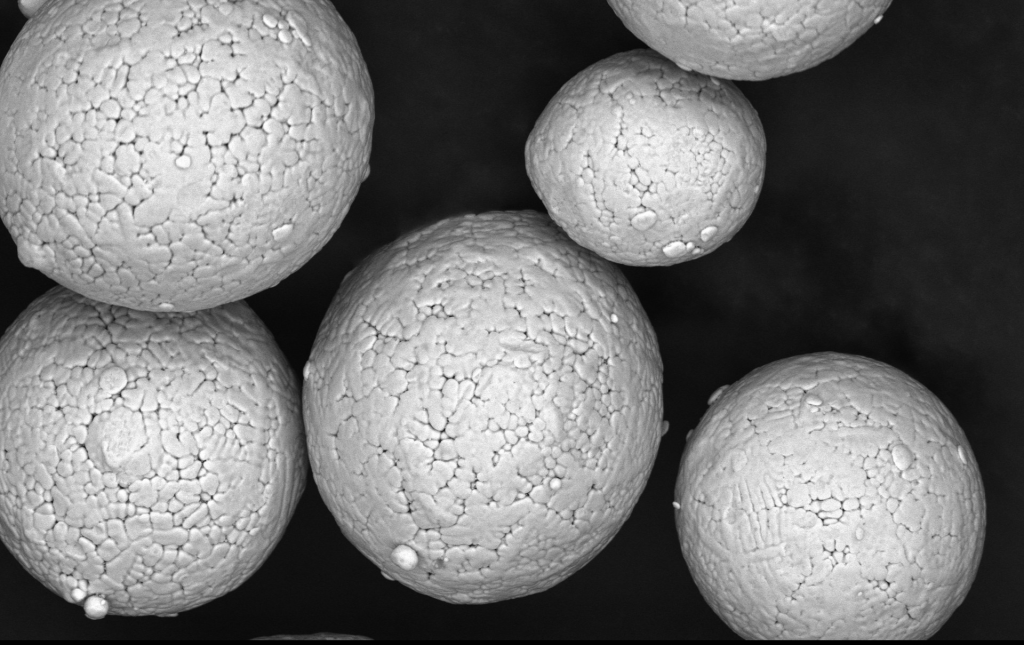

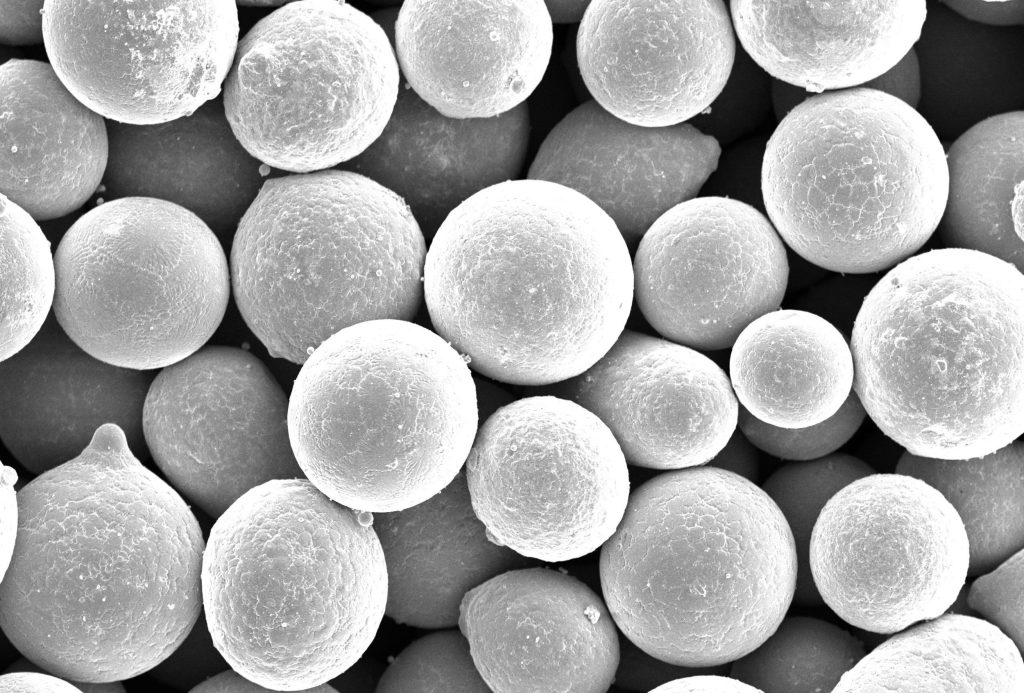

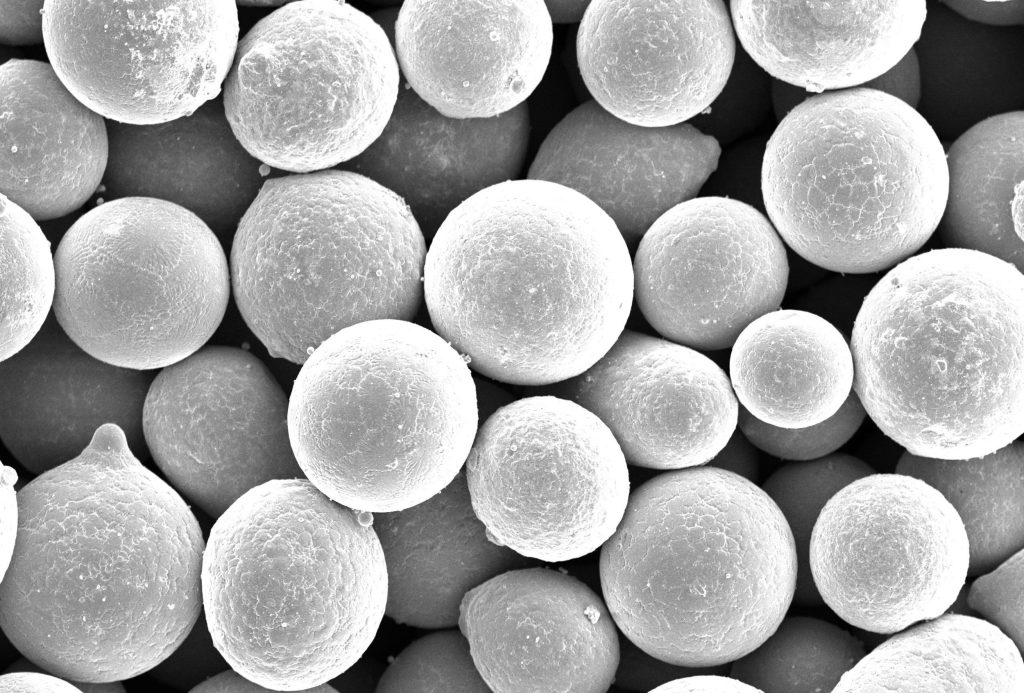

U.S.-based metal powder producer Continuum Powders has released two new copper-nickel alloy powders, OptiPowder C715 and OptiPowder C964, designed to perform reliably in challenging operating conditions. The powders deliver strong corrosion resistance, consistent thermal and electrical conductivity, and mechanical stability. Produced through the company’s proprietary Greyhound Melt-to-Powder (M2P) process using certified reclaimed feedstock, the alloys offer high performance while reducing environmental impact.

Engineered for marine, energy, and industrial applications, these copper-nickel powders withstand seawater corrosion, stress-corrosion cracking, and erosion caused by high-velocity particles. Their uniform mechanical properties across a wide temperature range make them suitable for multiple additive manufacturing methods, including laser and electron beam powder bed fusion, binder jetting, hot isostatic pressing, direct energy deposition, and thermal spray processes.

Precision and Sustainability in Manufacturing

The powders are produced with M2P atomization, converting reclaimed aerospace-grade metals into high-purity, spherical particles with consistent flow behavior. Each batch is rigorously analyzed under Continuum’s OptiVantage framework, ensuring reliable performance in large-scale production.

“Continuum’s primary mission is to provide customers with reliable, high-performance powders,” said Rob Higby, CEO Continuum Powders. “With the addition of C715 and C964, engineers working in marine, energy, and industrial sectors now have access to copper-nickel powders that combine exceptional corrosion resistance with the consistency required for production-grade additive manufacturing.”

Expanding Capabilities and Circular Practices

Both powders maintain stable mechanical behavior at high temperatures while offering excellent thermal and electrical conductivity. They are designed for ease of fabrication, strong weldability, and resistance to erosion from particles in fluid environments. Multiple particle size options, ranging from 10–45 µm to 45–106 µm, are available, with additional customization to match specific AM platforms and processing needs.

The new alloys complement the company’s Direct Powder Feeder, which recycles unused powder back into the atomization cycle, contributing to a more circular and resilient supply chain. Looking ahead, Continuum plans to broaden its alloy portfolio, invest in analytical and scrap-sourcing capabilities, and create co-development opportunities that allow customers to fine-tune chemistries, validate powders, and implement fully circular feedstock strategies.

Advances in 3D Printing of Metal Alloys

Continuum’s new copper-nickel powders arrive amid a wave of innovations in metal additive manufacturing, where researchers are exploring new alloys and processes to enhance performance and sustainability. At the Massachusetts Institute of Technology (MIT), researchers have developed a new aluminum alloy that is expected to transform the fabrication of lightweight, high-strength parts. Published in Advanced Materials, the study explores how rapid cooling during laser powder bed fusion allows aluminum to form metastable structures not achievable in traditional casting.

At Oak Ridge National Laboratory (ORNL), engineers are testing DuAlumin 3D, a newly developed aluminum alloy for 3D printing high-temperature automotive components. The alloy demonstrates superior printability and mechanical performance compared to conventional aluminum grades, while retaining excellent thermal properties.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Linkedin.

Featured image shows OptiPowder C96400. Image via Continuum Powders.

Source link

2025-12-19 11:00:00