![]()

Researchers at Kennesaw State University in the United States have found that adjusting 3D printing settings can nearly triple the strength of printed parts, paving the way for safer, more efficient designs in high-stakes applications like nuclear energy.

The project, supported by the Summer Undergraduate Research Program and the Sophomore Scholars Program, is led by Aaron Adams, assistant chair of the Department of Engineering Technology, and carried out by mechatronics engineering student Eric Miller at KSU’s START Lab. The team explores how subtle changes in lattice angles, densities, and internal channels influence material behavior. Adams notes that these improvements could help address inefficiencies in nuclear fuel systems, where tightly packed fuel pellets have little room to expand.

“Right now, the fuel is in the form of a pellet about the size of a penny, and the pellets are stacked together like a roll of coins,” said Adams, an associate professor of mechanical engineering technology.

“These fuel pellets are then placed inside a fuel rod. When the nuclear reaction begins, they heat up, expand, and come into contact with the rod wall. Because they have no room to expand, they must be removed before the fuel is completely depleted, limiting how much of the fuel can be used. Ultimately, we hope to achieve a 15 percent increase in fuel utilization using complex geometries.”

Simulation Challenges and Hands-On Innovation

Miller’s role spans model development, simulation setup, and Finite Element Analysis to test various lattice configurations—experience he says has stretched his skills beyond typical mechatronics coursework. He has long appreciated 3D printing’s accessibility, noting that even inexpensive desktop printers can produce functional parts for everyday use.

The team has faced challenges running high-resolution simulations, as detailed meshes for curved structures push the limits of the lab’s computing resources. Adams views these obstacles as part of the learning process and commends Miller’s persistence and initiative.

Miller is scheduled to present the group’s findings at an upcoming ASME conference and said the experience has reshaped his perspective. “Even when something appears to be a failure, it’s still a success because it tells us what direction not to take,” he said. “I’ve really appreciated this experience, and it’s been incredibly helpful for my growth.”

Mechanical Performance Optimization in Additive Manufacturing

Kennesaw State’s research reflects a larger trend in AM: precise control over internal geometries, whether at the microscale or nanoscale, can dramatically enhance mechanical performance.

Recent studies at Penn Engineering, the University of Pennsylvania School of Arts & Sciences, and Aarhus University have shown that introducing controlled disorder into 3D printed mechanical metamaterials improves crack resistance. Laboratory tests demonstrated that materials incorporating non-uniform lattice geometries exhibited 2.6 times greater toughness than those with uniform, repeating patterns. Computational simulations revealed that slight variations in node positions distribute stress more effectively, reducing crack propagation. These findings highlight that small geometric adjustments, rather than changes in material composition, can significantly improve mechanical properties.

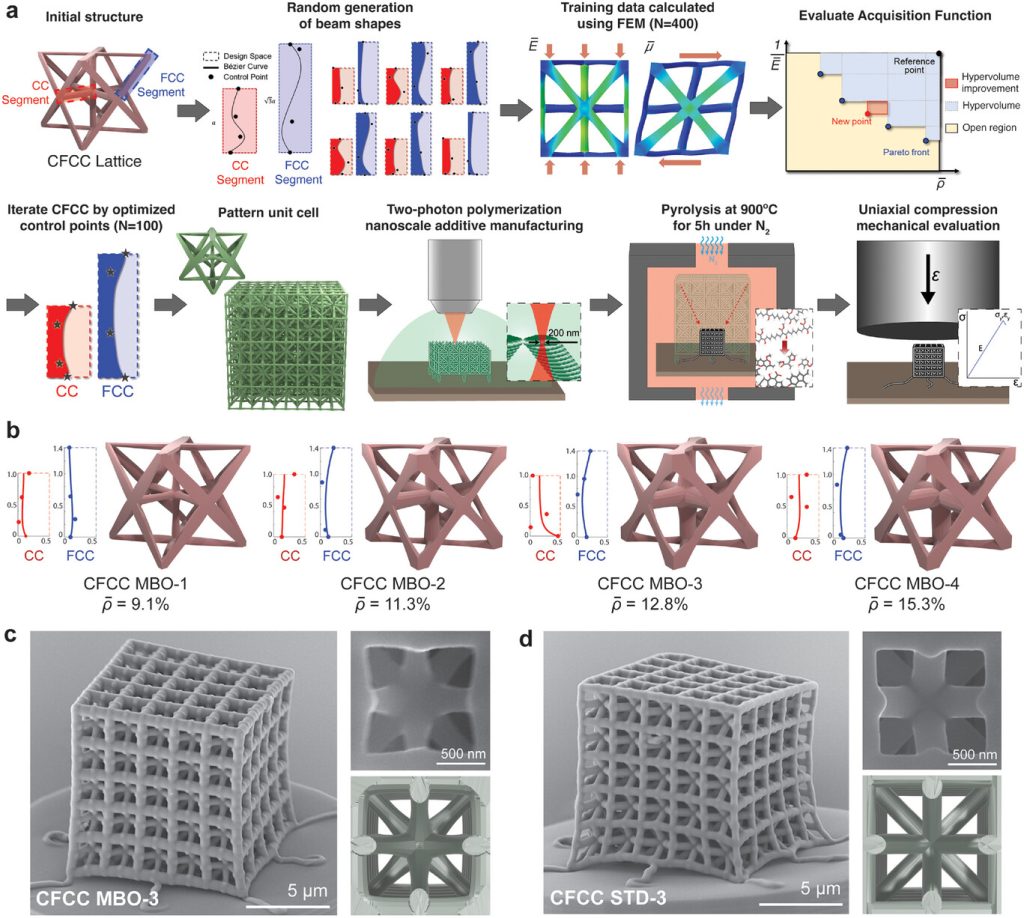

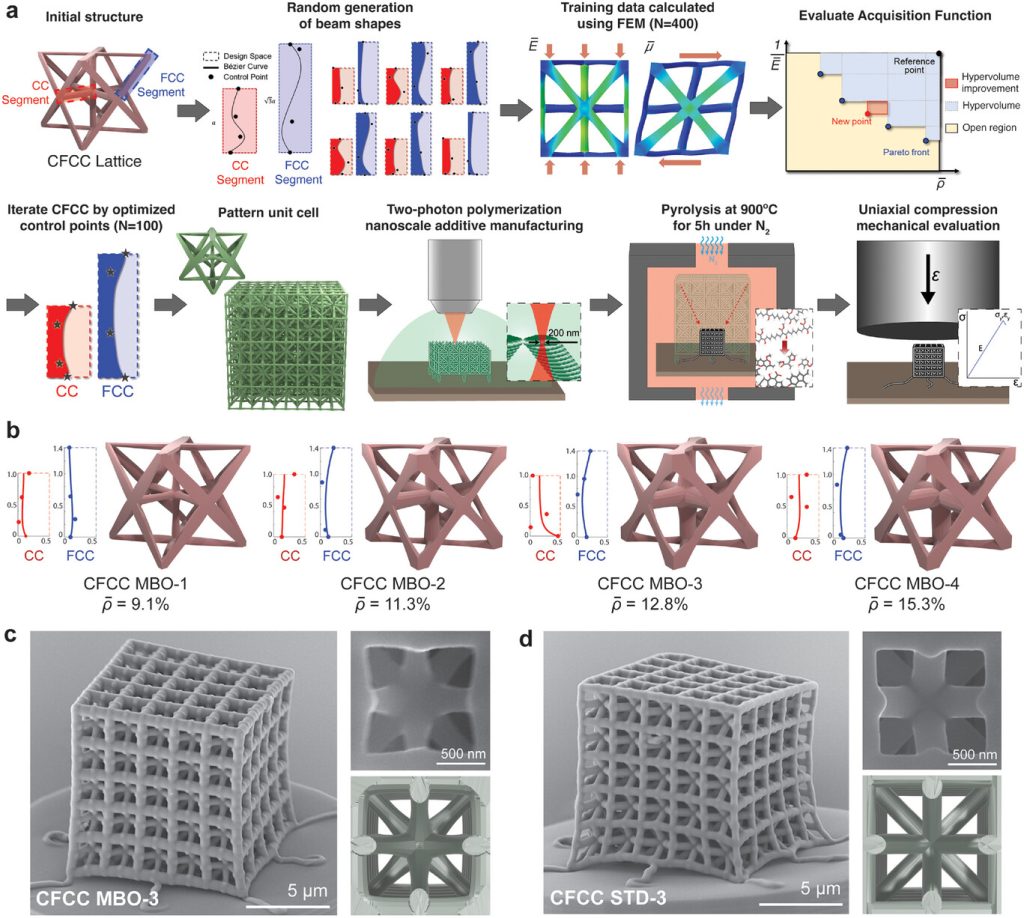

Similarly, researchers at the University of Toronto have developed carbon nanolattices with an ultrahigh specific strength of 2.03 MPa·m³/kg at densities below 215 kg/m³. Using multi-objective Bayesian optimization (MBO) combined with two-photon polymerization (2PP), they refined nanoscale lattice structures to eliminate nodal stress concentrations, a common failure point in traditional nanoarchitected materials. After fabrication, the polymer lattices were pyrolyzed at 900°C to produce pyrolytic carbon, further enhancing structural integrity and mechanical performance at the atomic level.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Linkedin.

Featured image shows Eric Miller and Aaron Adams. Photo via Kennesaw State.

Source link

2025-12-15 08:43:00