![]()

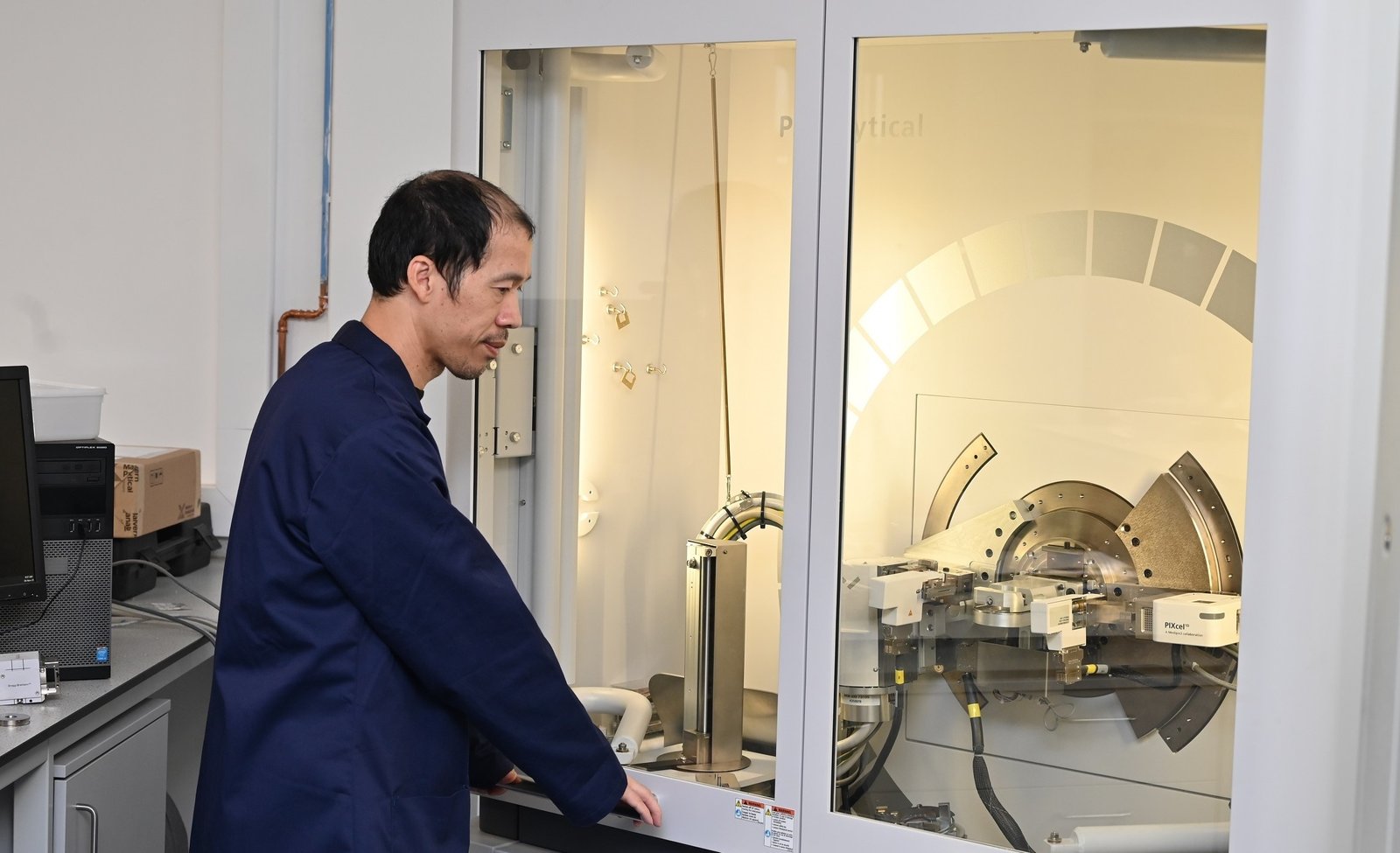

UK-based research organization Materials Processing Institute (MPI) has introduced a high-temperature X-ray Diffraction (XRD) system that allows researchers and industrial partners to study materials at temperatures up to 1600°C. This system enables real-time observation of phase transformations in ceramics, slags, minerals, and metal alloys under conditions relevant to industrial processes such as casting, kilns, and foundry operations.

The capability has been implemented as part of the PRISM research programme, funded by Innovate UK, which supports innovation, productivity, and sustainability in the UK metals and steel sector as it transitions toward net-zero and circular-economy practices.

High-Temperature Research Applications

Demand for in-situ XRD analysis at temperatures up to 1600°C has been increasing, as both industry and academia seek to understand material behavior during heating and cooling cycles. MPI’s existing platinum hot stage XRD operates up to around 1400°C, but researchers in the Advanced Materials Characterisation Centre have designed a tantalum-based hot stage capable of providing stable and precise measurements at higher temperatures while reducing contamination and wear.

This capability allows MPI to support clients across a range of sectors, including steelmaking, metallurgical refining, refractory and furnace lining design, glass and mineral processing, cement and slag production, pyrometallurgy, advanced ceramics and composites, high-temperature additive manufacturing, and applications in the energy, hydrogen, and chemical industries.

“This in-house technology gives manufacturers the confidence to innovate, optimise their processes and understand how materials behave in real-world conditions. It reinforces our commitment to providing world-class research expertise through the PRISM programme,” said Chris Oswin, CEO of the Materials Processing Institute.

Advances in 3D Printing of Functional and Extreme-Temperature Materials

MPI’s work on high-temperature materials analysis complements other independent research efforts in 3D printing and advanced materials. At the University of Notre Dame, researchers developed a machine learning-assisted extrusion 3D printing process to produce high-performance thermoelectric materials. Their data-driven approach combined Bayesian optimization with Gaussian Process Regression and Support Vector Machines to create bismuth antimony telluride (BiSbTe) structures with a room-temperature zT of 1.3, the highest reported for printed thermoelectrics, while maintaining complex geometries suitable for waste heat recovery.

Elsewhere, NASA’s Glenn Research Center developed the GRX-810 alloy, a nickel-cobalt-chromium oxide-dispersion-strengthened material designed for 3D printing spacecraft components. Using a resonant acoustic mixing technique, the team created a material capable of withstanding extreme temperatures up to 2,000°F for extended periods, while enabling more complex geometries than conventional manufacturing allows.

The 3D Printing Industry Awards are back. Make your nominations now.

Do you operate a 3D printing start-up? Reach readers, potential investors, and customers with the 3D Printing Industry Start-up of Year competition.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Linkedin.

Featured image shows The high-temperature X-ray Diffraction. Photo via MPI.

Source link

2026-01-06 10:20:00