![]()

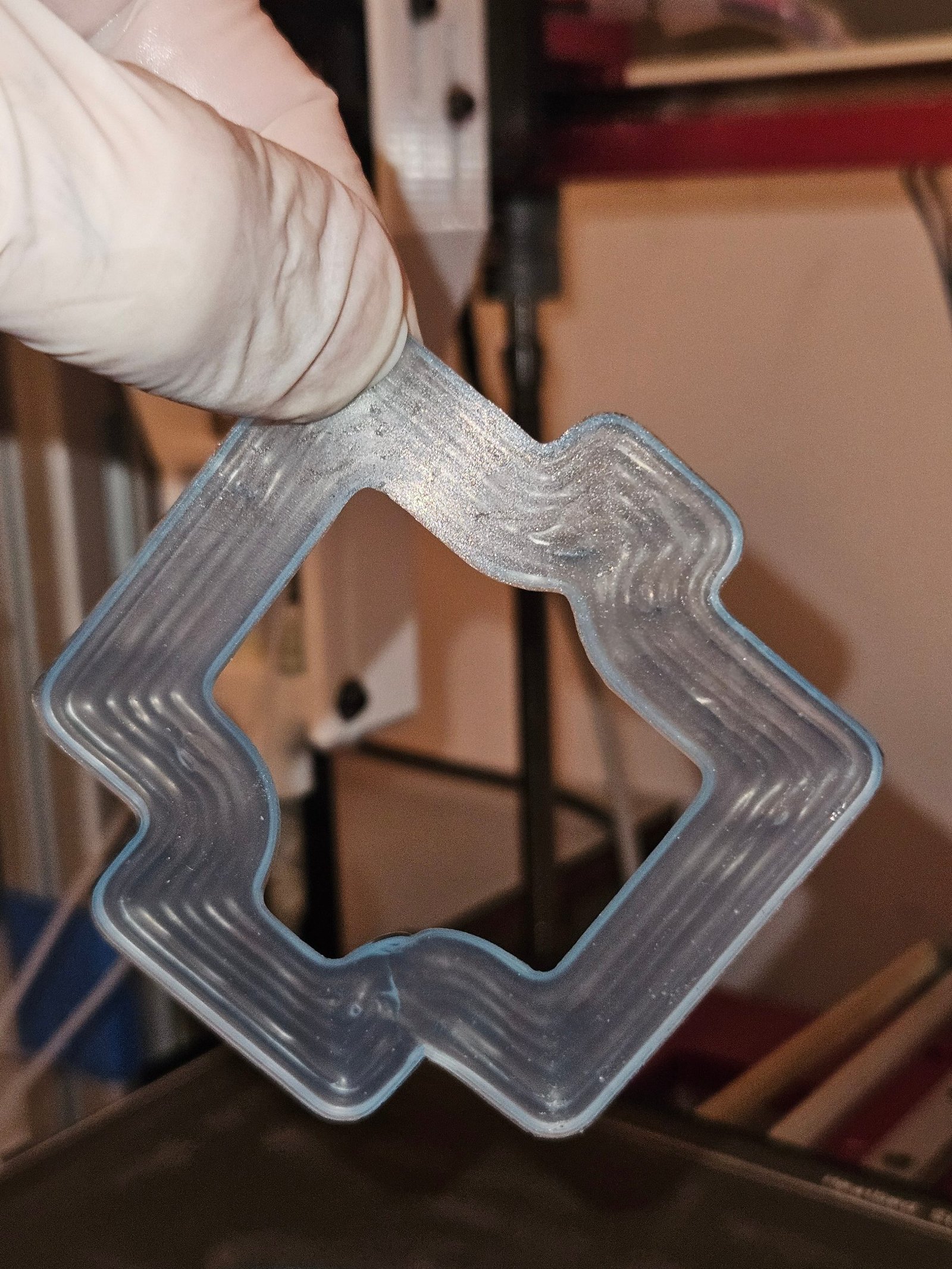

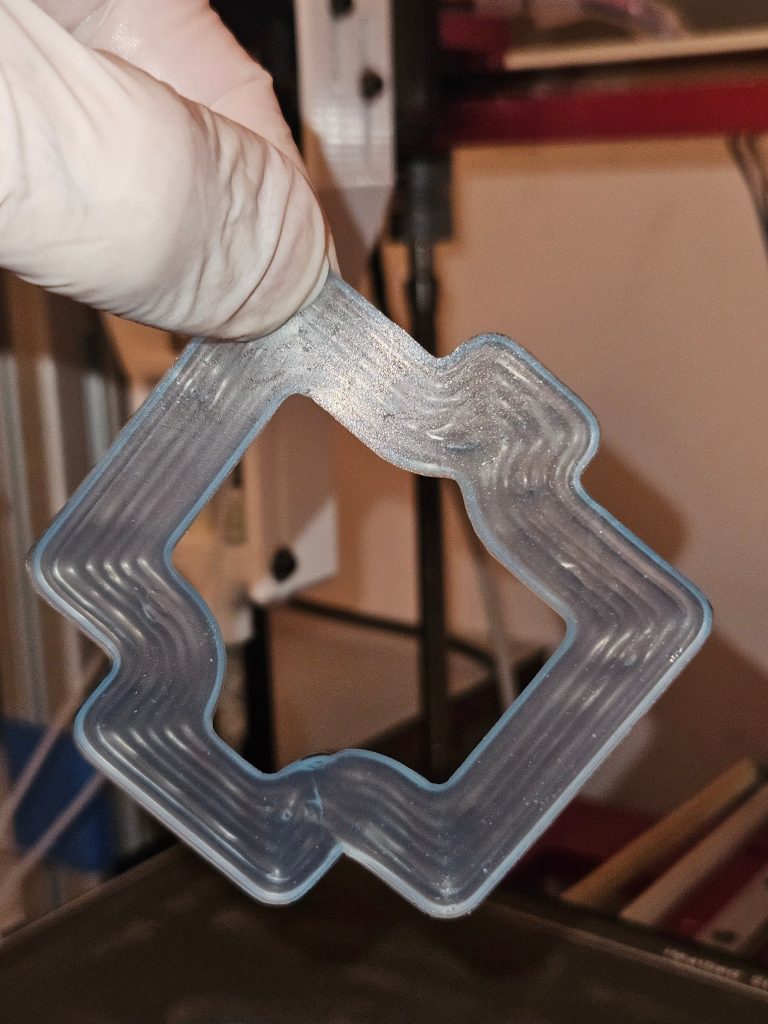

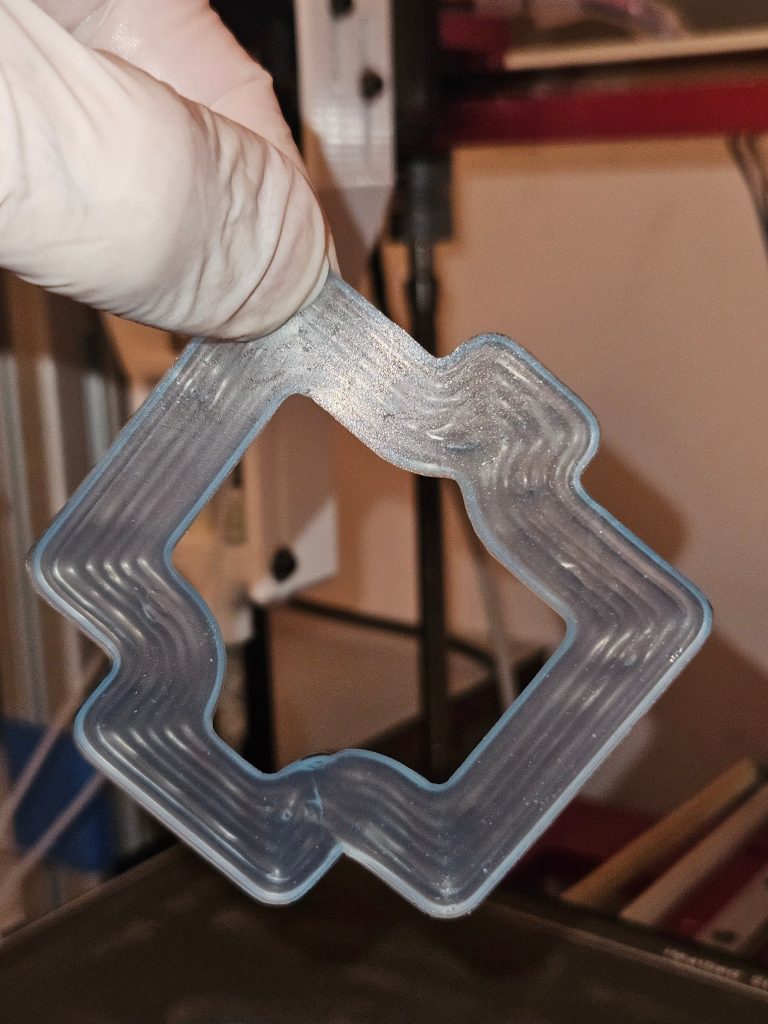

Filament2, a company specializing in innovative 3D printing materials, announced the launch of the world’s first silicone filament compatible with standard FDM 3D printers at Formnext 2024. This development promises to expand the capabilities of additive manufacturing across various industries by removing the necessity for specialized equipment.

Silicone is highly regarded for its flexibility, heat resistance, and durability, making it a preferred material in industries such as medical devices, automotive engineering, and consumer electronics. However, integrating silicone into 3D printing processes has traditionally been difficult due to the complexity and high costs associated with specialized machinery. Filament2’s new filament addresses these challenges by enabling the extrusion of pure silicone using any standard FDM printer. This innovation not only simplifies the manufacturing process but also makes silicone accessible to a wider range of users and applications.

In addition to silicone, Filament2 has introduced core-tube technology that allows the creation of filaments from a variety of paste materials, including polyurethane, ceramics, adhesives, and even edible substances like chocolate. This versatility opens up numerous possibilities for additive manufacturing, enabling users to experiment with materials that were previously incompatible with standard 3D printers.

The introduction of silicone filament is poised to impact several key sectors. In the medical field, the ability to produce custom silicone parts can enhance the development of implants, prosthetics, and surgical tools, offering more tailored solutions for patients. Automotive manufacturers stand to benefit from the capability to create flexible, heat-resistant gaskets and seals in-house, potentially reducing lead times and costs. Consumer electronics designers can explore the creation of durable components suitable for high-heat and flexible applications, while industrial prototyping can become faster and more cost-effective, bridging the gap between initial design and full-scale manufacturing.

Silicone Integration in 3D Printing

Spectroplast, a Swiss company specializing in silicone 3D printing, recently completed its Series A financing round led by HZG Group, with existing investor AM Ventures also participating. This funding aims to expand Spectroplast’s patented silicone materials into new industries, addressing the growing demand for customized manufacturing solutions. Originating as a spin-out from ETH Zurich, Spectroplast focuses on developing materials specifically tailored for additive manufacturing using Stereolithography (SLA) and Digital Light Processing (DLP) technologies. The company’s advancements have made silicone more accessible for industrial applications, particularly in sectors like medical technology, robotics, and consumer electronics.

Similarly, Lynxter, a company specializing in silicone 3D printing systems, has made significant strides in making silicone printable. In a 2023 interview, Thomas Batigne, Co-founder and President of Lynxter, discussed the challenges and solutions associated with silicone 3D printing. Lynxter’s S300X 3D printer, designed for both silicone and polyurethane materials, exemplifies the technological advancements necessary to accommodate silicone’s unique properties. Innovations such as gel supports and intelligent XY supports have addressed issues related to silicone’s inherent cohesion and layering challenges, enabling high-resolution prints without extensive post-processing. Batigne emphasized Lynxter’s role in advancing silicone 3D printing, highlighting its potential applications in medical devices, soft robotics, and automotive components.

Your voice matters in the 2024 3D Printing Industry Awards. Vote Now!

What will the future of 3D printing look like?

Which recent trends are driving the 3D printing industry, as highlighted by experts?

Subscribe to the 3D Printing Industry newsletter to stay updated with the latest news and insights.

Stay connected with the latest in 3D printing by following us on Twitter and Facebook, and don’t forget to subscribe to the 3D Printing Industry YouTube channel for more exclusive content.

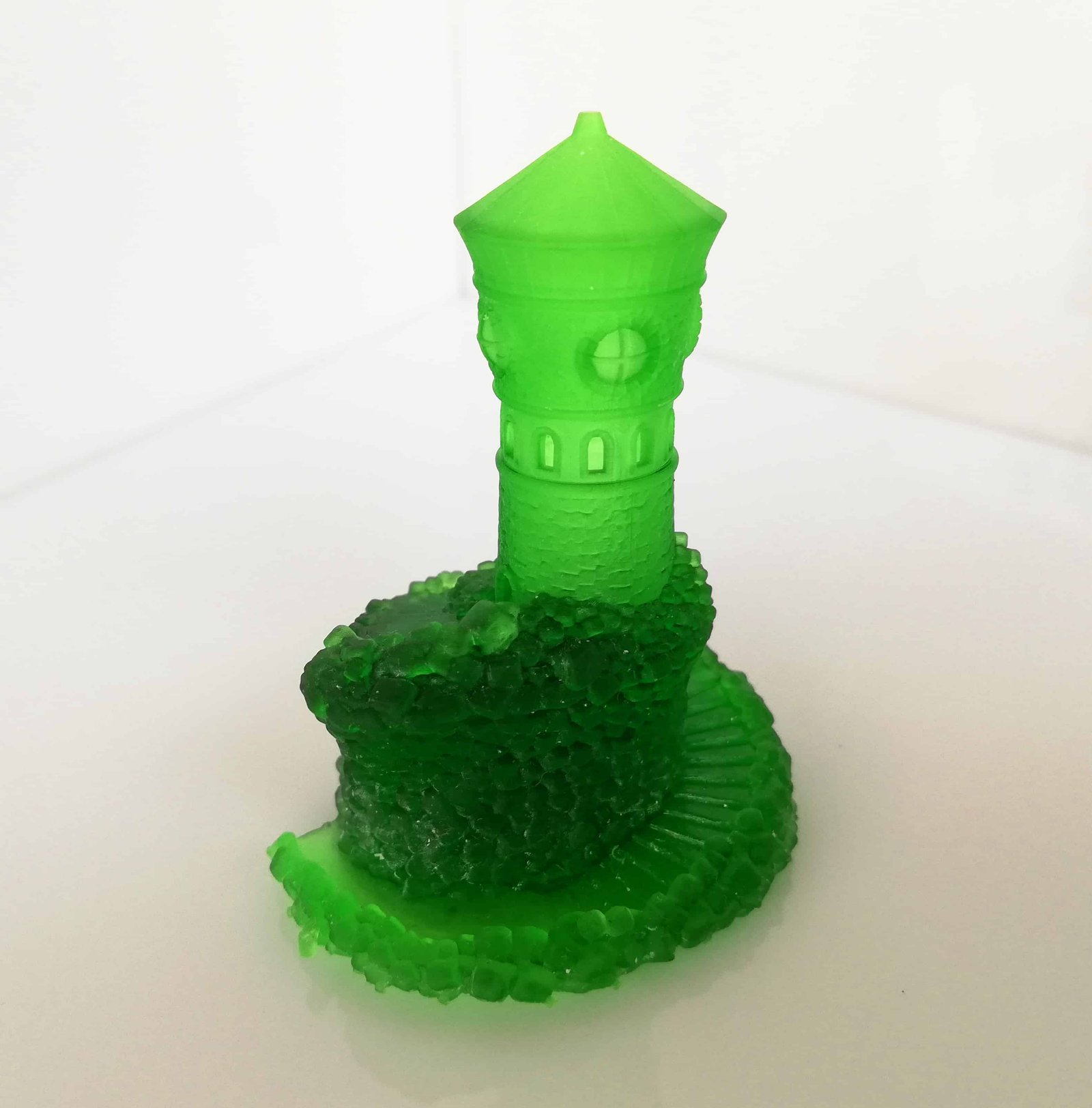

Featured image shows a close-up of the world’s first silicone filament. Photo via Filament2.

Source link

2024-12-02 09:34:00